Application technology

In our application technology labs, a team of highly trained ultrasonic experts performs detailed feasibility studies and test runs to find the optimal solutions for your applications.

THE ULTRASONIC LAB – OUR CENTER OF EXCELLENCE

- Seam design consultation by ultrasonic experts and application technicians

- Test series on pre-series parts

- Feasibility studies

- Verification of process parameters for an ideal welding process

- Leak test

- Burst pressure tests

- Thermography

- Tensile tests

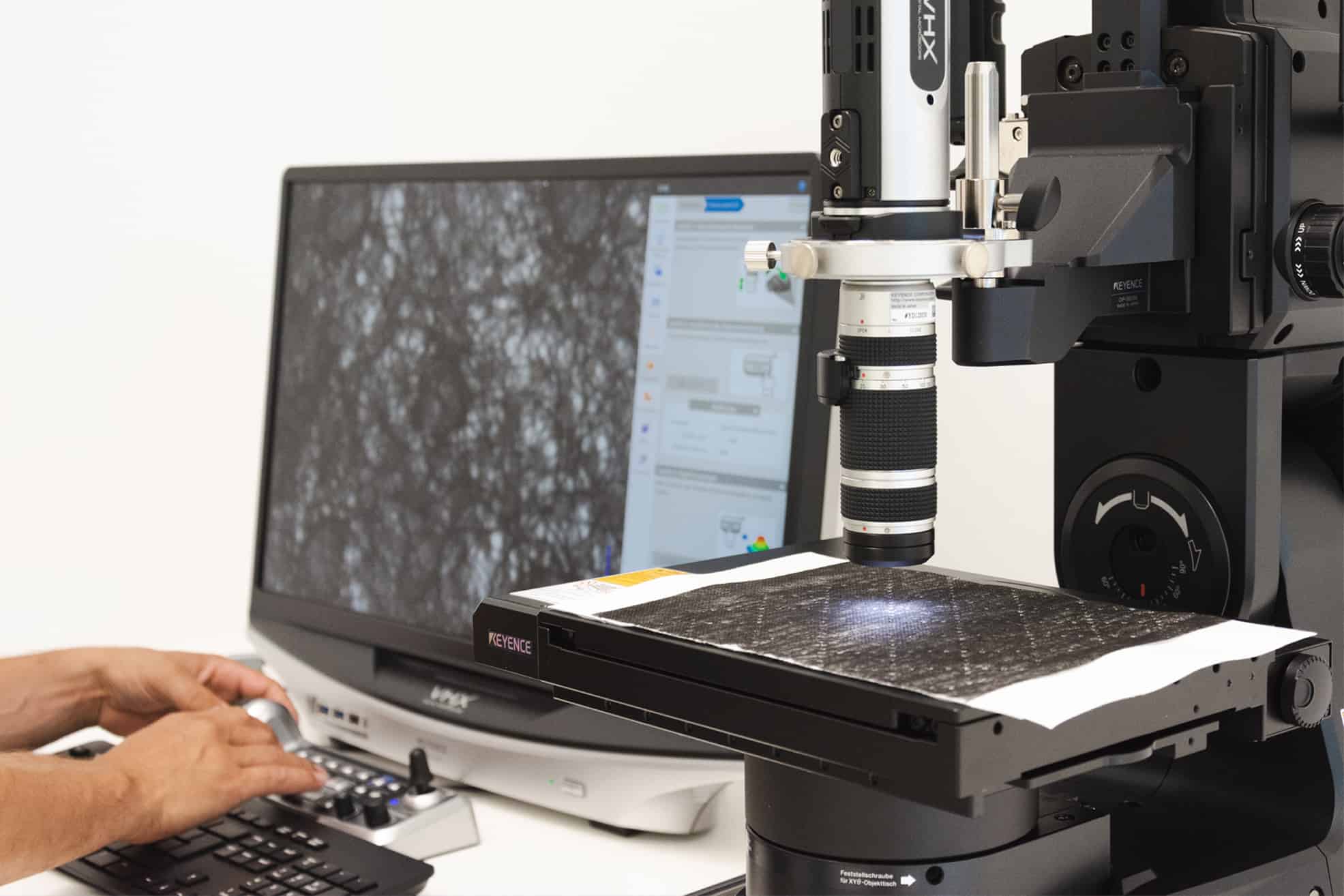

- Microtome sections of welding seams

- Validation processes

SHOWROOM

Here you get a detailed insight into the possibilities of the latest ultrasonic technologies:

- Training course delivery

- Application demonstrations

- Product range presentations

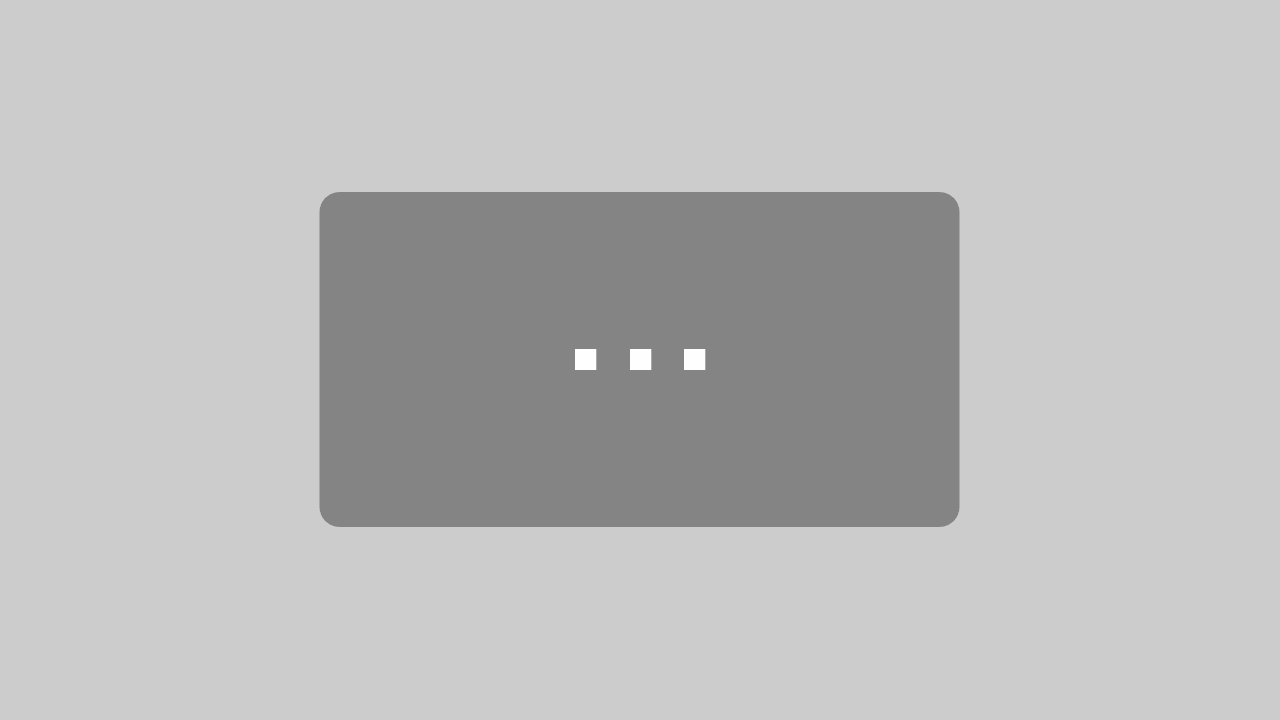

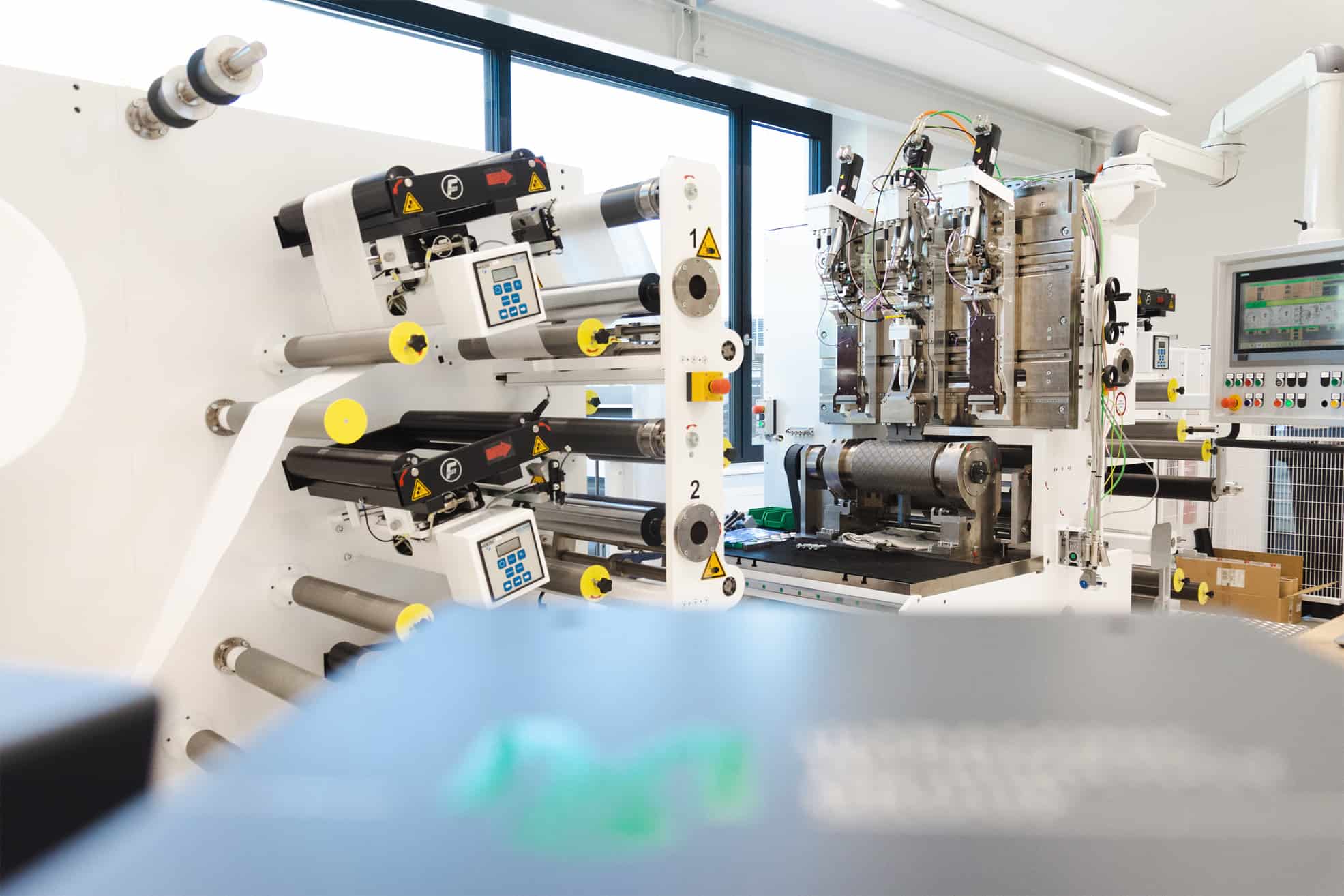

Insights into our application lab:

COMPETENCE CENTER ETTLINGEN

Testing, evaluations, and optimisations of various welding tasks take place in two application laboratories and a measurement and analysis laboratory, as well as the in-house production from rotary dies to complete systems.

- Application-technical consulting of your welding tasks

- Support with the design of rotary dies

- Conduction of feasibility studies

- Welding trials to determine the process parameters

- Individualised process optimisation

- Problem solving for problematic welding applications

- Inspection of the quality characteristics (impermeability, porosity, stability)

- Microscopic analysis of the welding joints in 3D

- Preparation of samples and pre-series production