Ultrasonic feed units MS sonxACT

FEATURES AND VERSIONS

FEATURES

- Fast and efficient exchange of welding stack via quick-changing system

- Reduced investment costs and shorter installation times thanks to tandem units with up to three sonotrodes

- Modular and flexible use

- Easy machine integration due to compact shape and sleek design

- Stable design for demanding weld qualities, even at high welding pressures, thanks to double guide

VERSIONS

- Frequencies: 40, 35, 30, 20 kHz

- Stroke: 60–250 mm

- Options: Integrated depth stop, stroke measuring system, swivel unit

Servo-electrically controlled feed units: Highest precision and energy efficiency

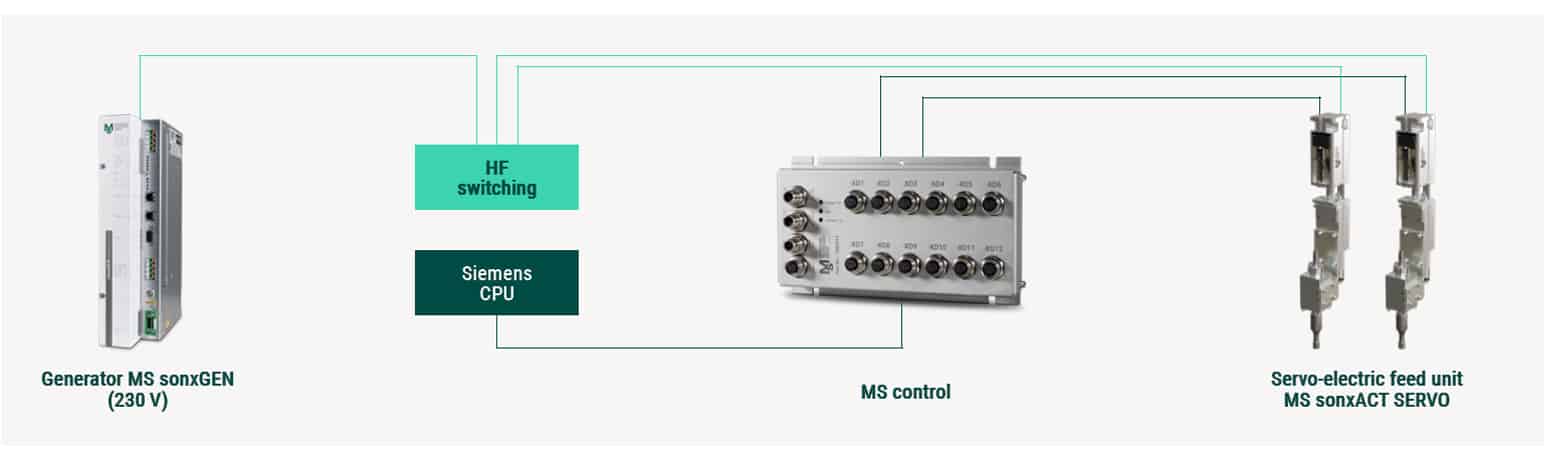

The servo-electrically driven MS sonxACT SERVO feed units in the MS sonxMAC range of custom machines are used for ultrasonic welding of complex surface and

riveted connections.

In demanding applications, they replace pneumatic feed units in machine and system engineering. The MS sonxACT SERVO guarantees very precise and continuous welding, thanks to the individually controlled feed rate. The welding quality and energy efficiency are increased by MS’ innovative control.

BENEFITS

- Compact design, thus saving machine space

- Precisely adjustable welding profiles

- Control unit specially designed and individually developed by MS

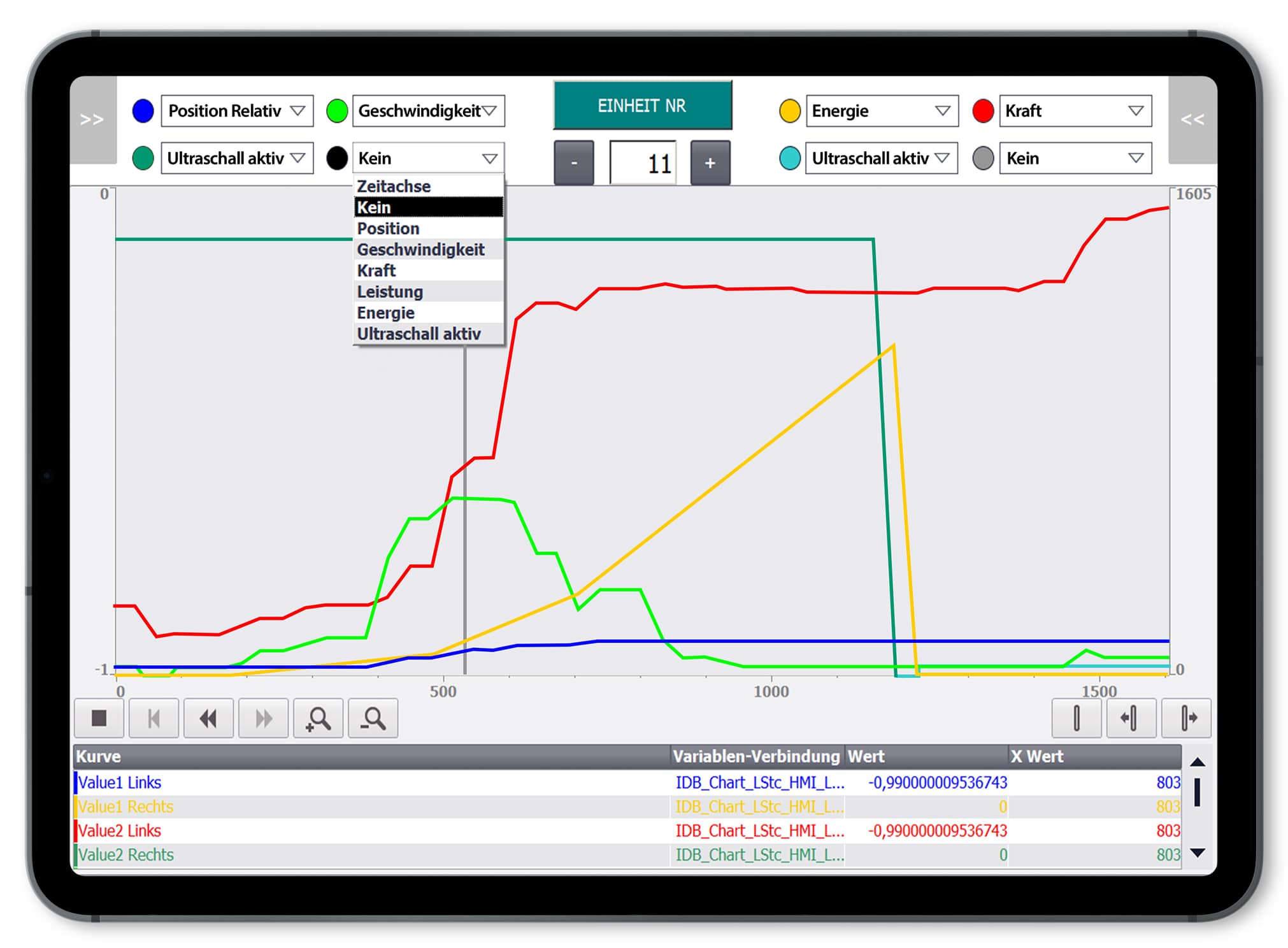

- Very good reproduction possibilities through monitoring and analysis of the parameters (position, force, energy, speed)

- In order to meet the highest quality requirements in the application, servo drive technology was used instead of a stepper motor

- Save energy costs thanks to the high efficiency

- Individual set-up of the workspace with proven ultrasonic welding units

- Highest strength values for the welding result

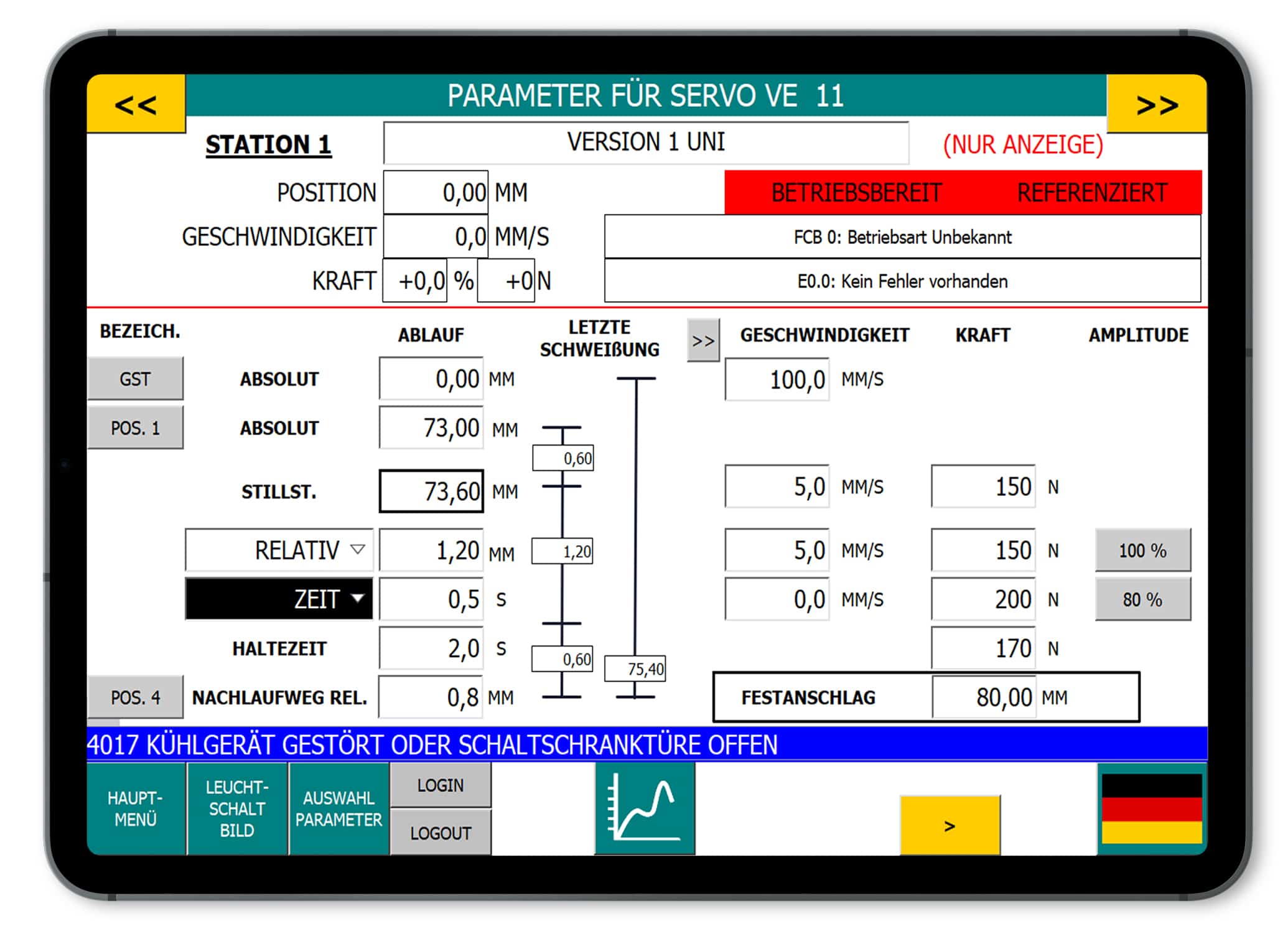

- Welding applications completely and flexibly adjustable via the HMI (user interface) – from Basic to Advanced

- Reduce CO2 emissions sustainably while increasing production efficiency

- Very long service life of the units in best MS quality

- Plug and play: thanks to the same size of pneumatic and servo-electric feed units

- You are investing in intelligent and seamless connectivity for your Industry 4.0 production

With the innovative servo drive concept of the machines with MS sonxACT SERVO, your technological leap into the future will also be successful!

Options can be set individually over two welding phases by:

- Absolute welding path

- Relative welding path

- Time

- Energy

- Force

Analyses of the welding result are possible on the control panel.

CONTROL

APPLICATION EXAMPLES

- Pressure sensitive materials

- Thin-walled materials

- NFPP and GFPP components

- Rear spoiler

- Door panels

- Bumpers

- Decorative parts

- Top rolls

- Instrument panels

VARIANTS

STANDARD – MS sonxACT SERVO 35-100

COMPACT – MS sonxACT SERVO 35-100 XS

REINFORCED – MS sonxACT SERVO 35-100 RF

- Positioning accuracy up to 0.01 mm

- Feed rate from 0.1 mm/s up to 220 mm/s possible

- Frequency classes 20 kHz, 30 kHz, 35 kHz, 40 kHz

PRODUCT INQUIRY

Always there for you

Do you have any questions about the product or a special application? We are happy to help you. You are welcome to send us an e-mail at vertrieb@ms-ultraschall.de.

But some things have to be discussed personally. Use our callback form. We will contact you. Fast and competent.