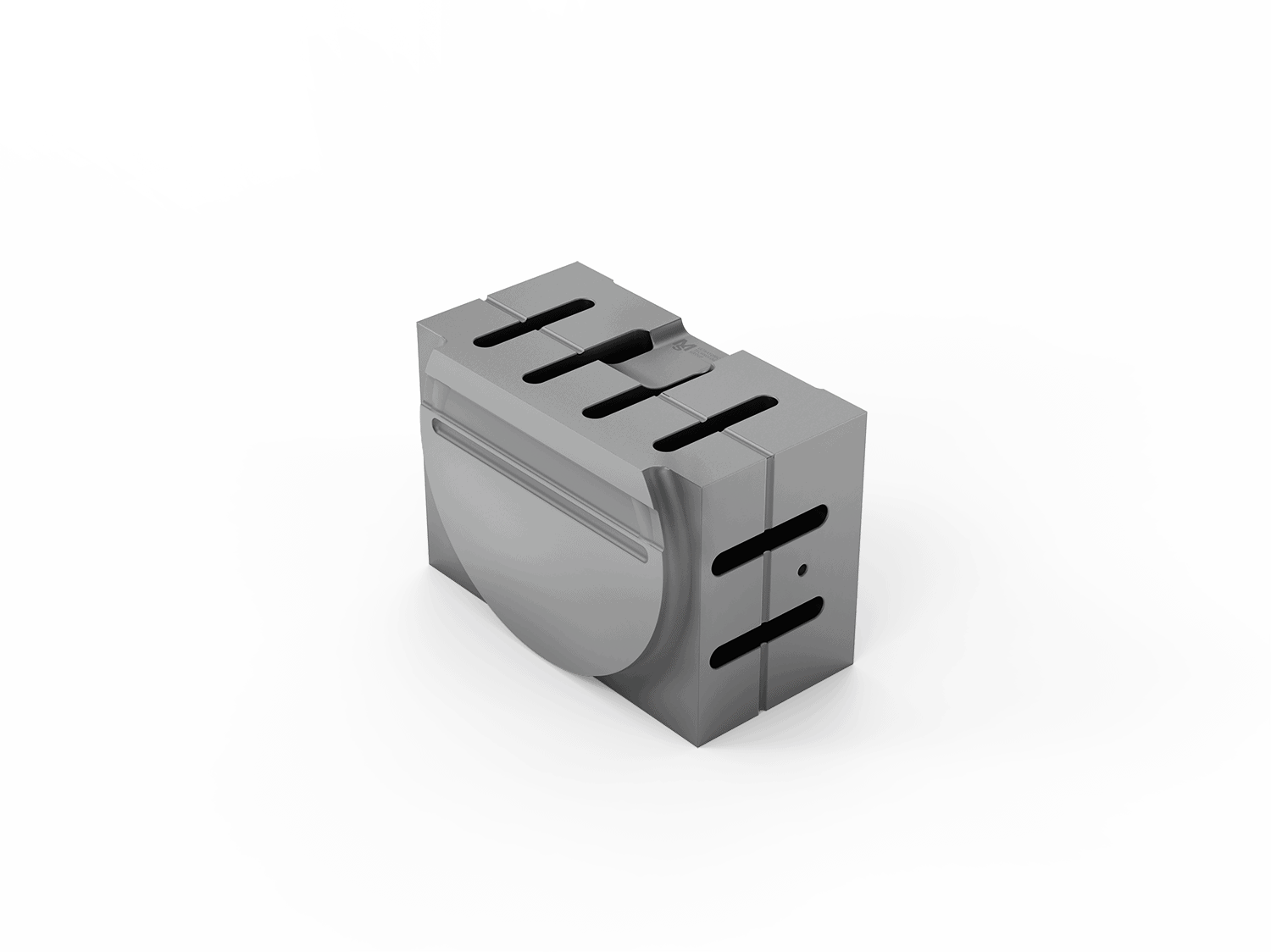

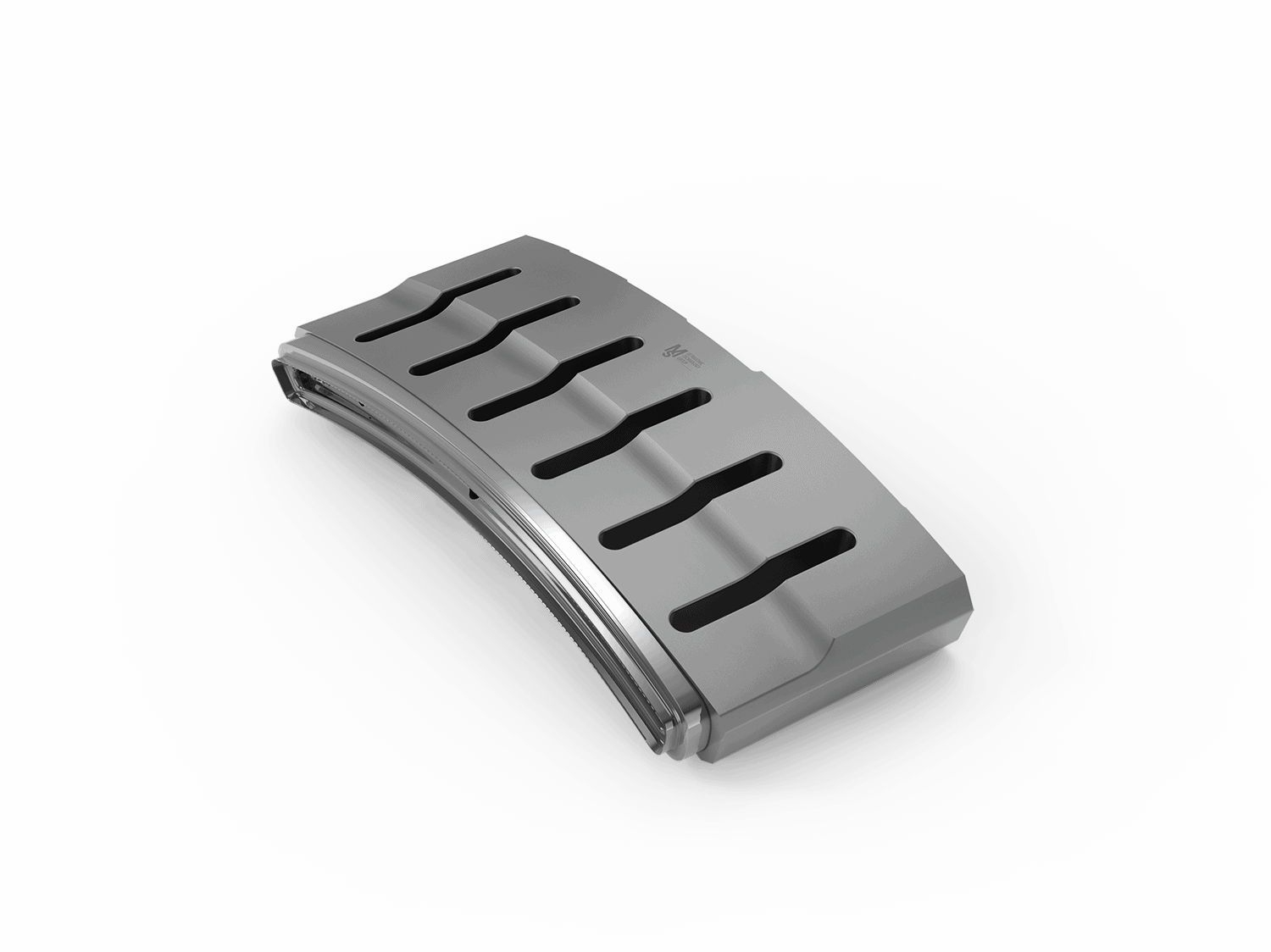

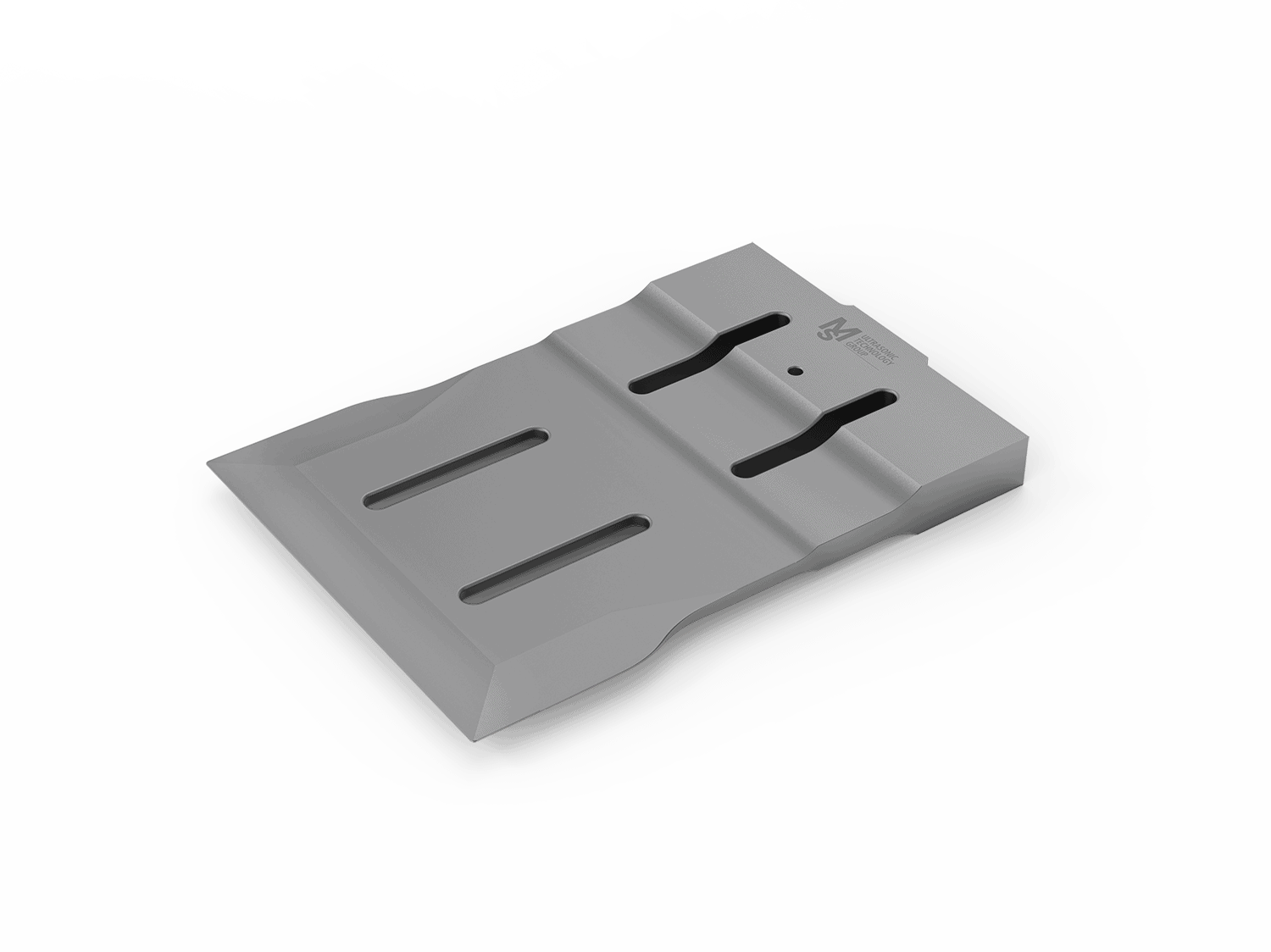

Ultrasonic sonotrodes MS sonxSON

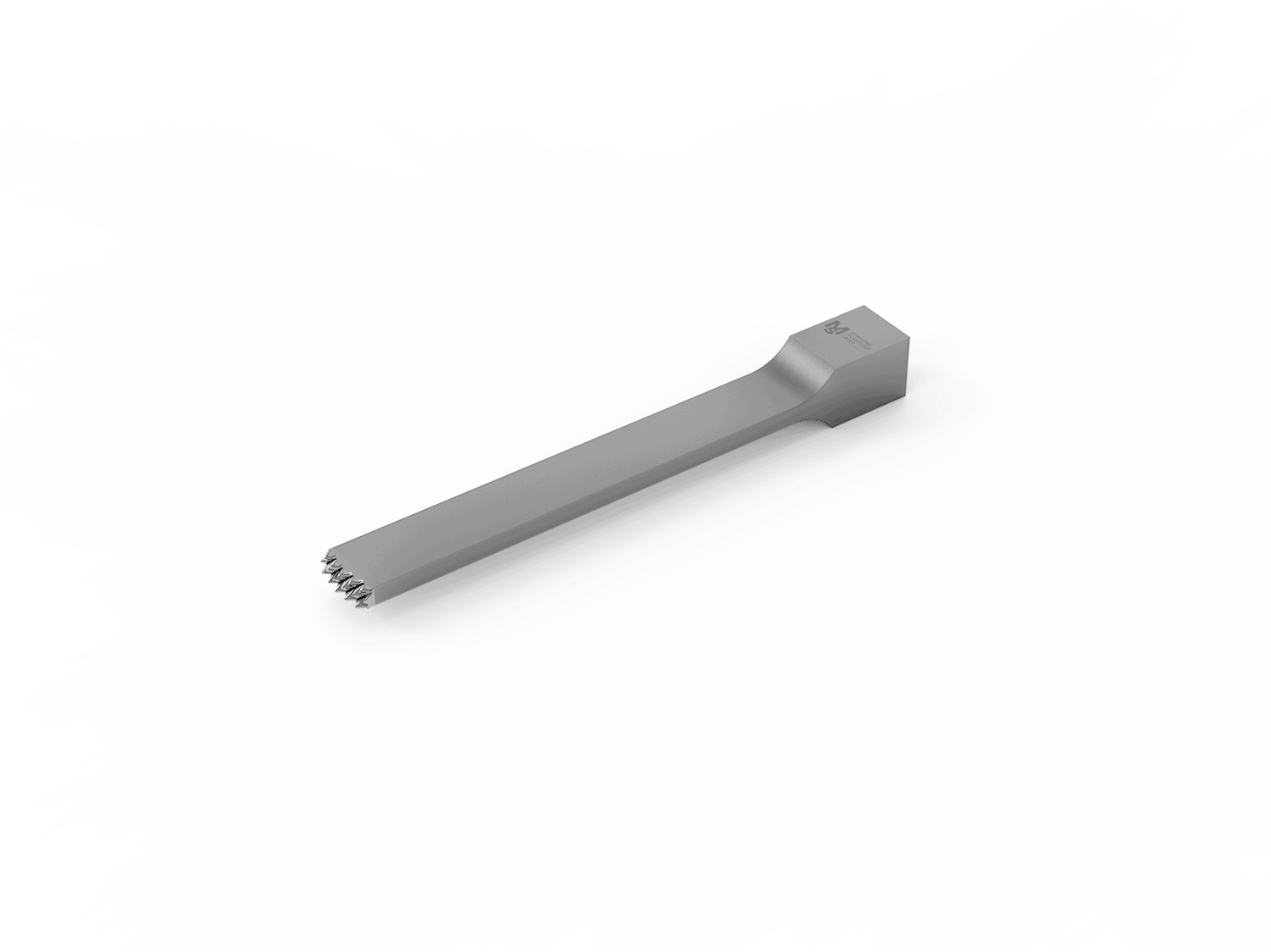

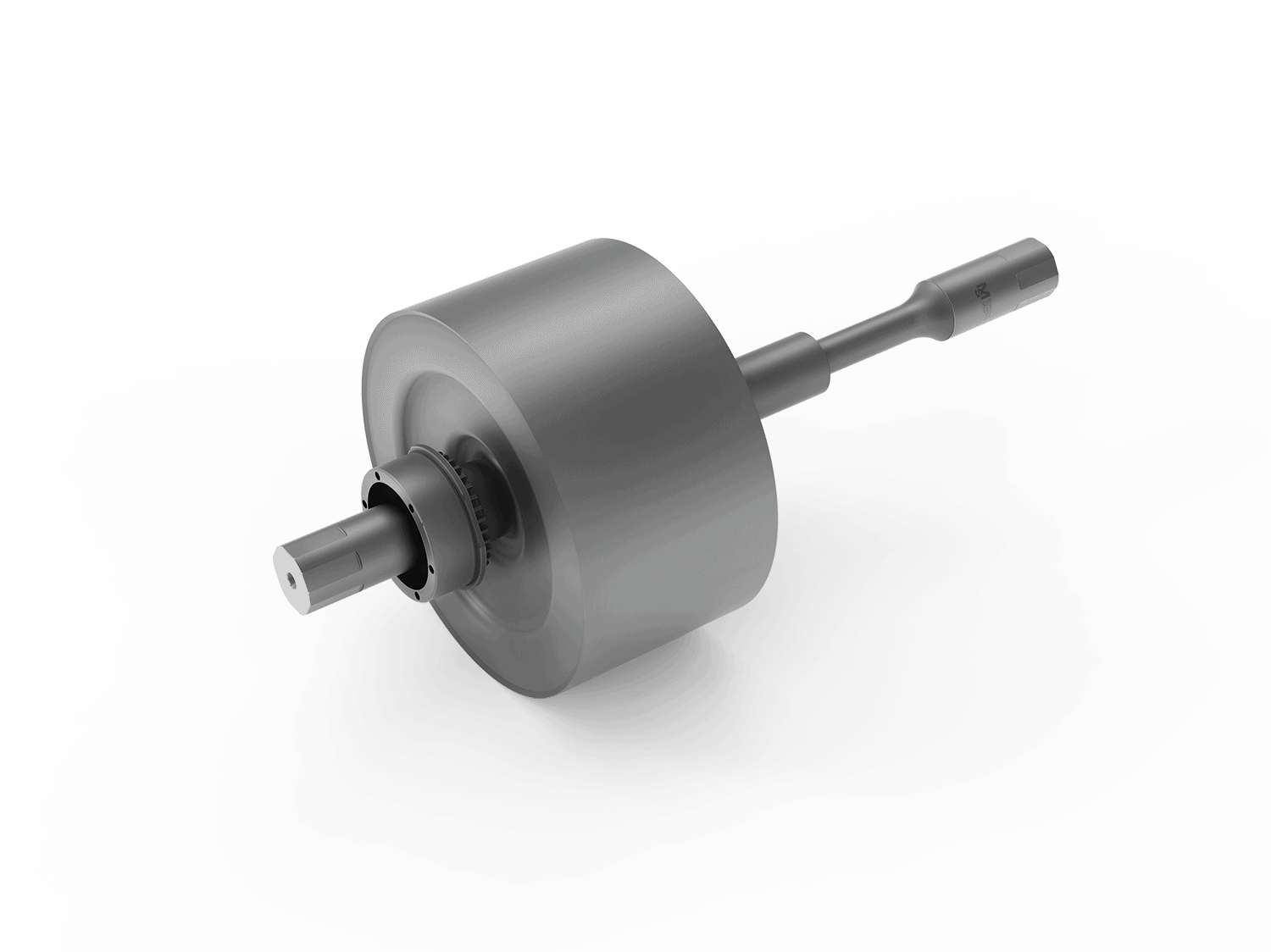

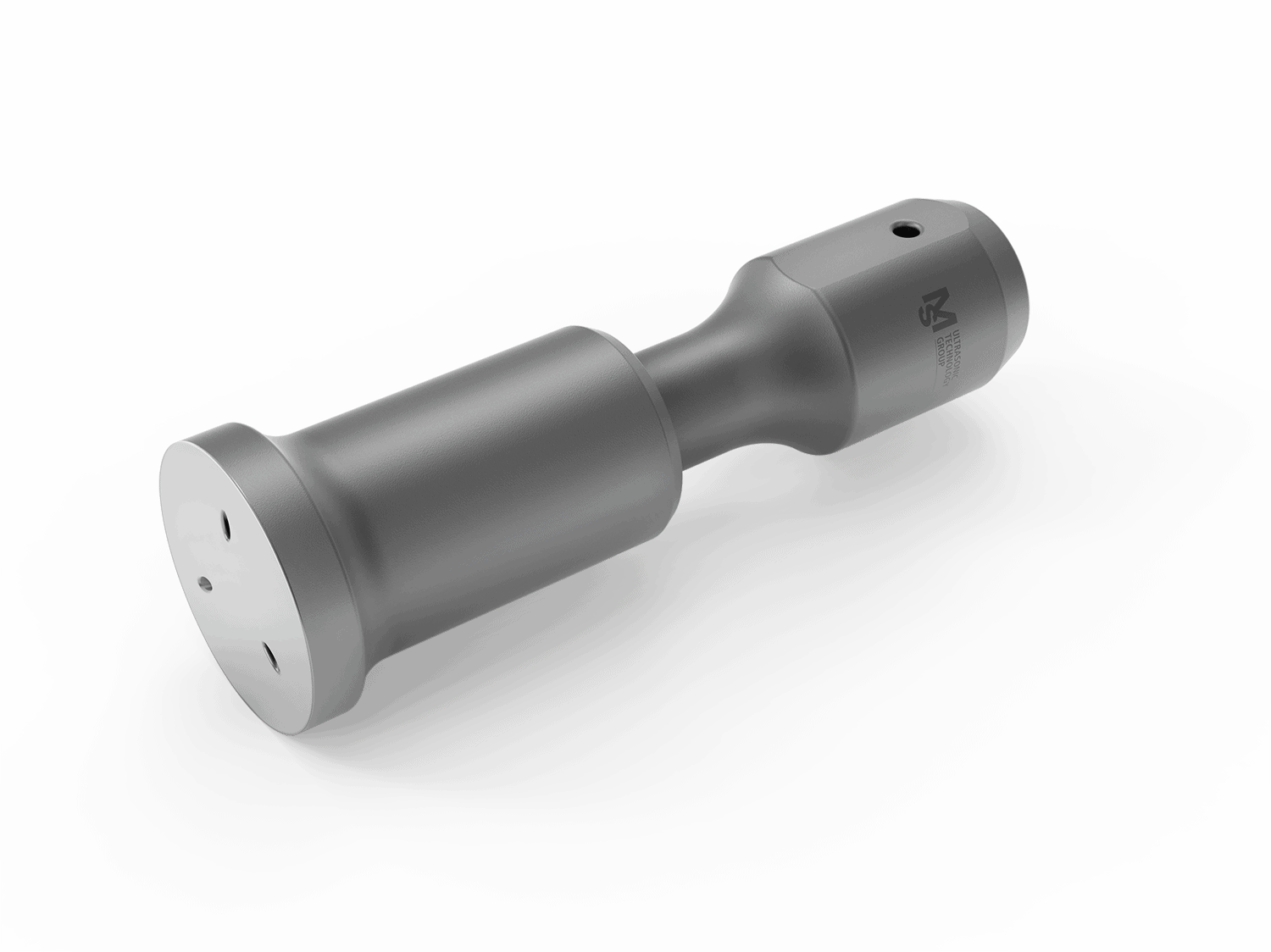

With their detailed part design, FEM calculation, careful selection of materials, precision manufacturing and precise coordination, MS sonxSON sonotrodes deliver the highest quality. The MS Ultrasonic Technology Group offers a complete range of sonotrodes that are tailored, calculated, manufactured and tuned to suit the respective component. Another type of sonotrode is the torsional sonotrode, which produces torsional vibrations as opposed to the longitudinal vibrations of conventional sonotrodes.

FEATURES AND VERSIONS

FEATURES

- Sonotrodes tuned to frequency and amplitude

- Sonotrode geometries and anvil versions to suit any application

- Long service life thanks to individual selection of the sonotrode material to suit the respective plastic

- Optimal welding results due to precise resonance behavior of the sonotrodes

- Long service life due to FEM calculation of the optimum resonance behavior

- Stable process with low thermal expansion thanks to innovative receptor design

VERSIONS

- Frequencies: 40 kHz, 35 kHz, 30 kHz, 20 kHz

- Materials: titanium, steel, aluminum, various coatings

- MS sonxAMP amplitude boosters available in many variants

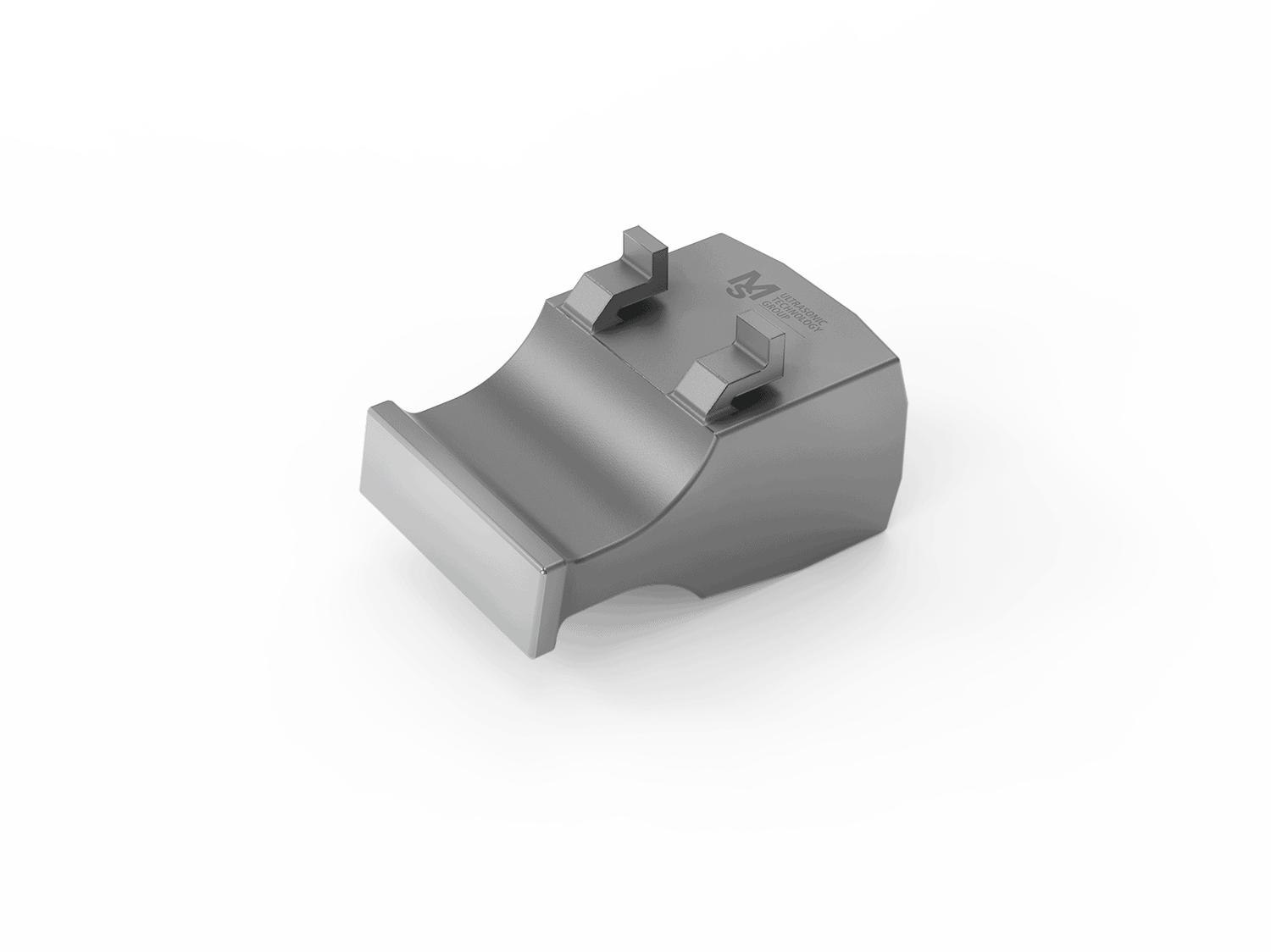

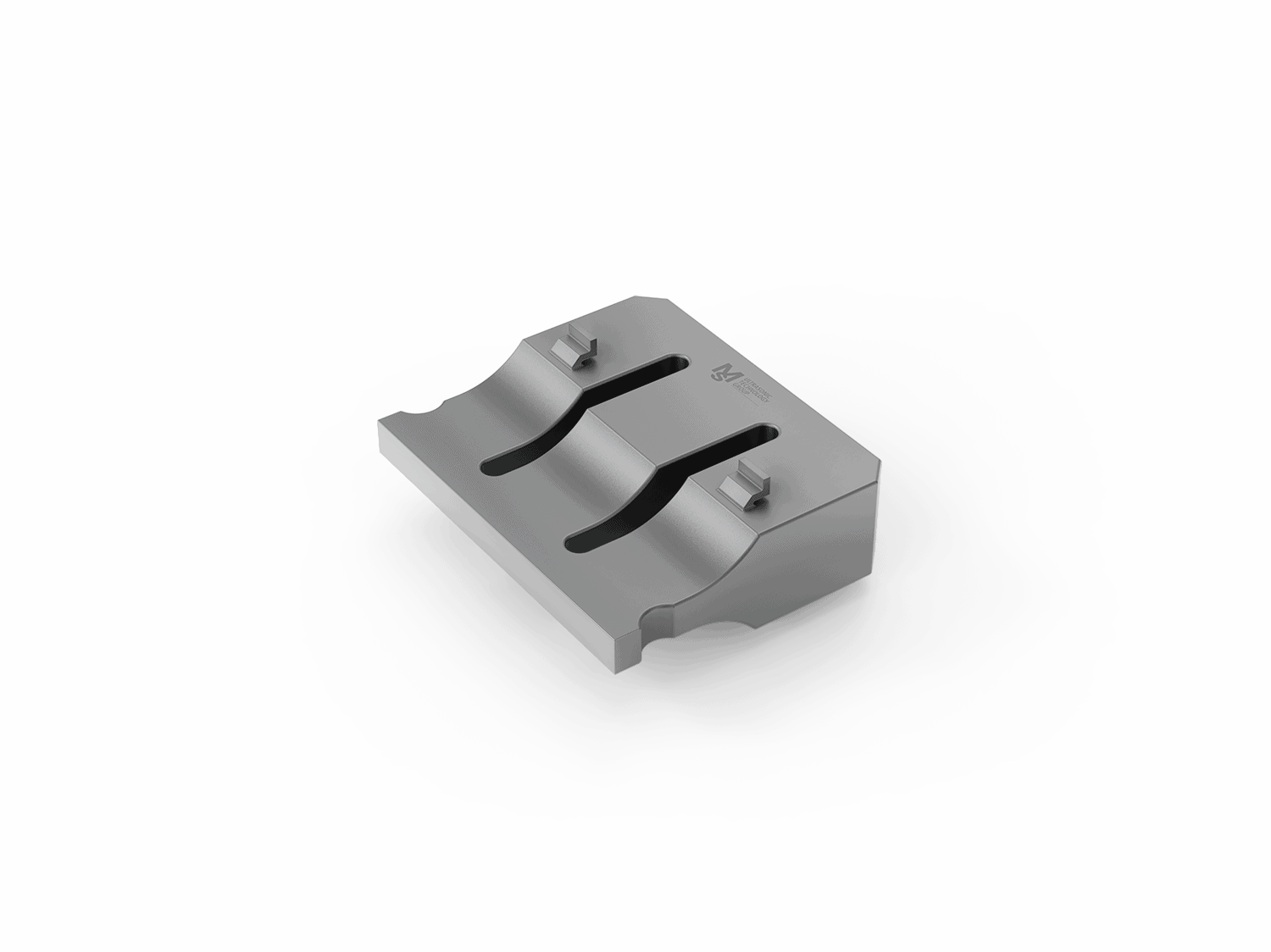

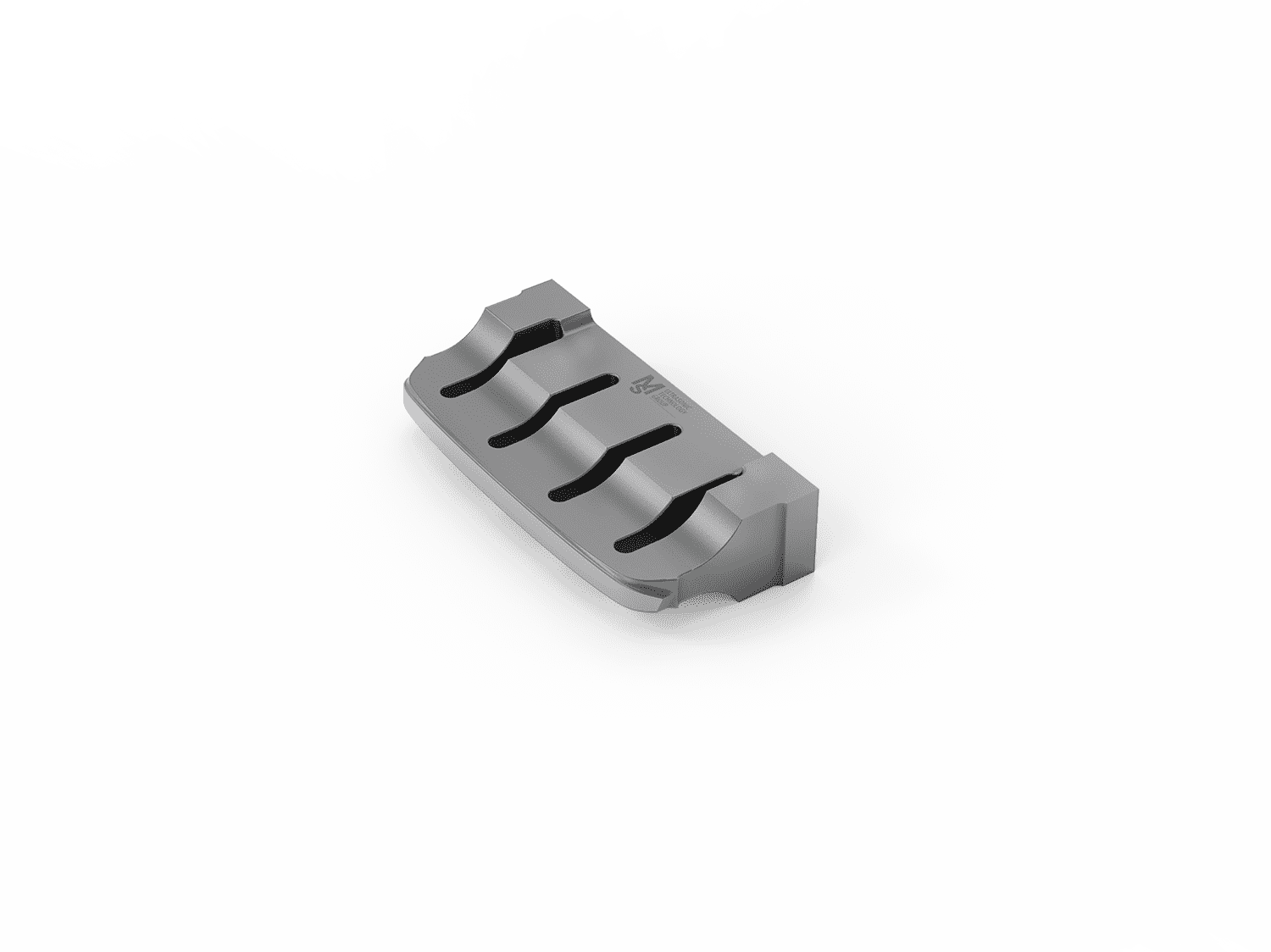

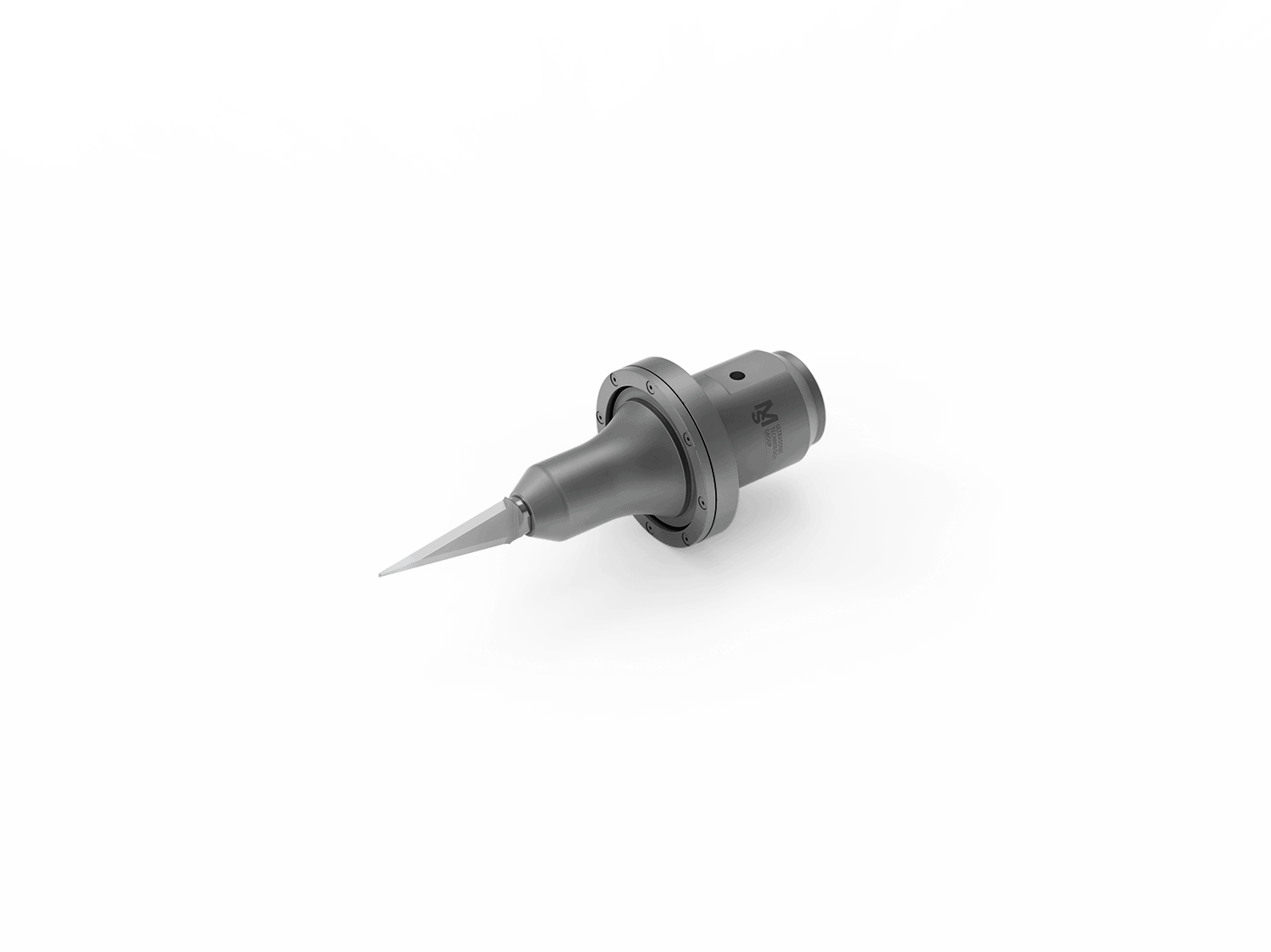

Gentle and efficient processing thanks to the torsional sonotrode

The patented torsional sonotrode from the MS Ultrasonic Technology Group gently and precisely processes membranes, films and injection molded parts. These sonotrodes are used in the MS sonxTOP series machines as well as in the MS sonxMAC custom machines.

Torsional ultrasonic welding is a high frequency friction welding process. Vibrations are introduced tangentially, the sonotrode always takes the upper join partner with it and moves it horizontally to the lower component. Due to the high frequency of 20–35 kHz, the amplitude and the pressure, a melting occurs between the two join partners as a result of gentle friction. In comparison with longitudinal vibrations, weak points such as electronics, bridges and ribs within the component are subjected to even less stress.

BENEFITS

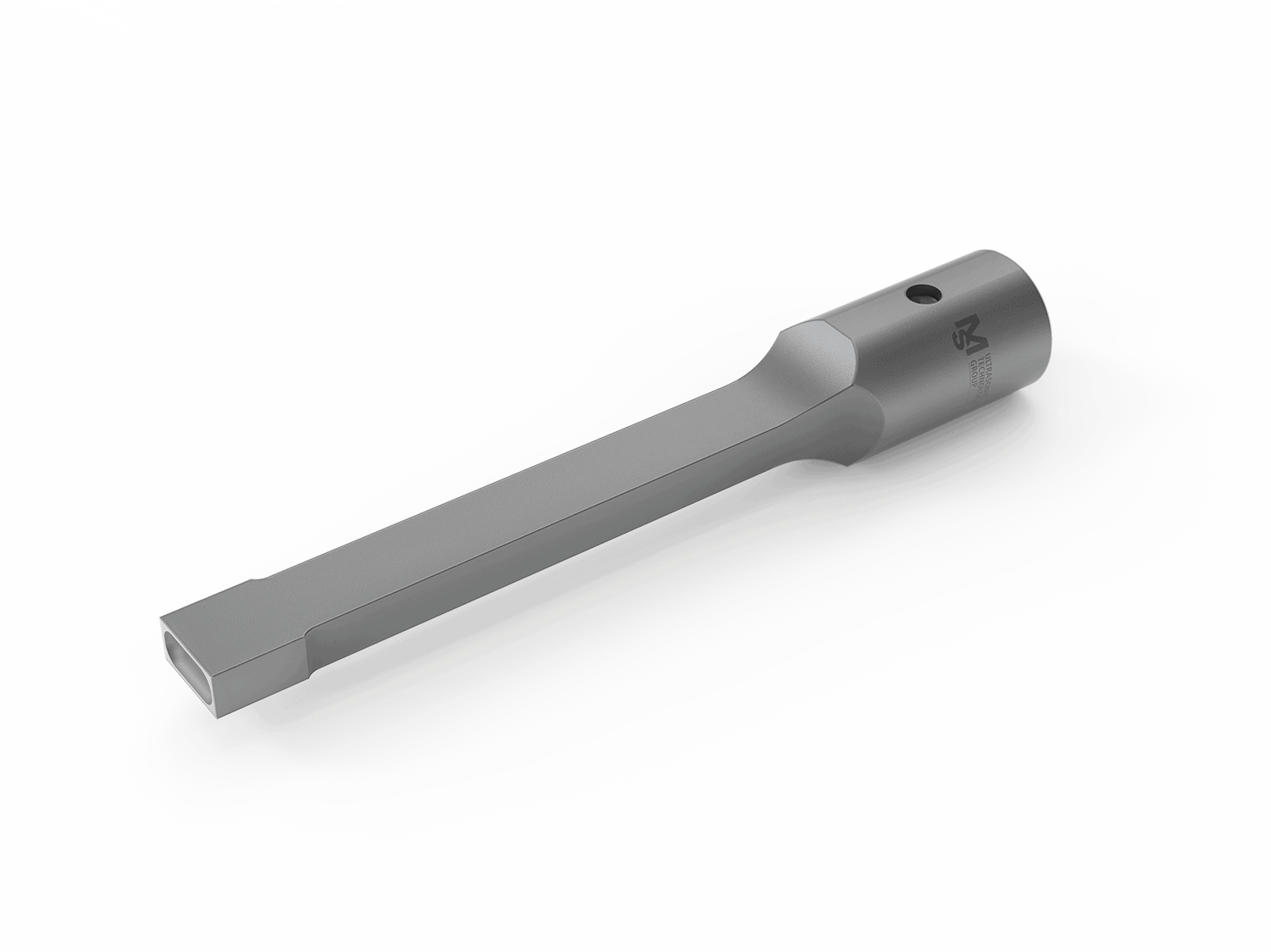

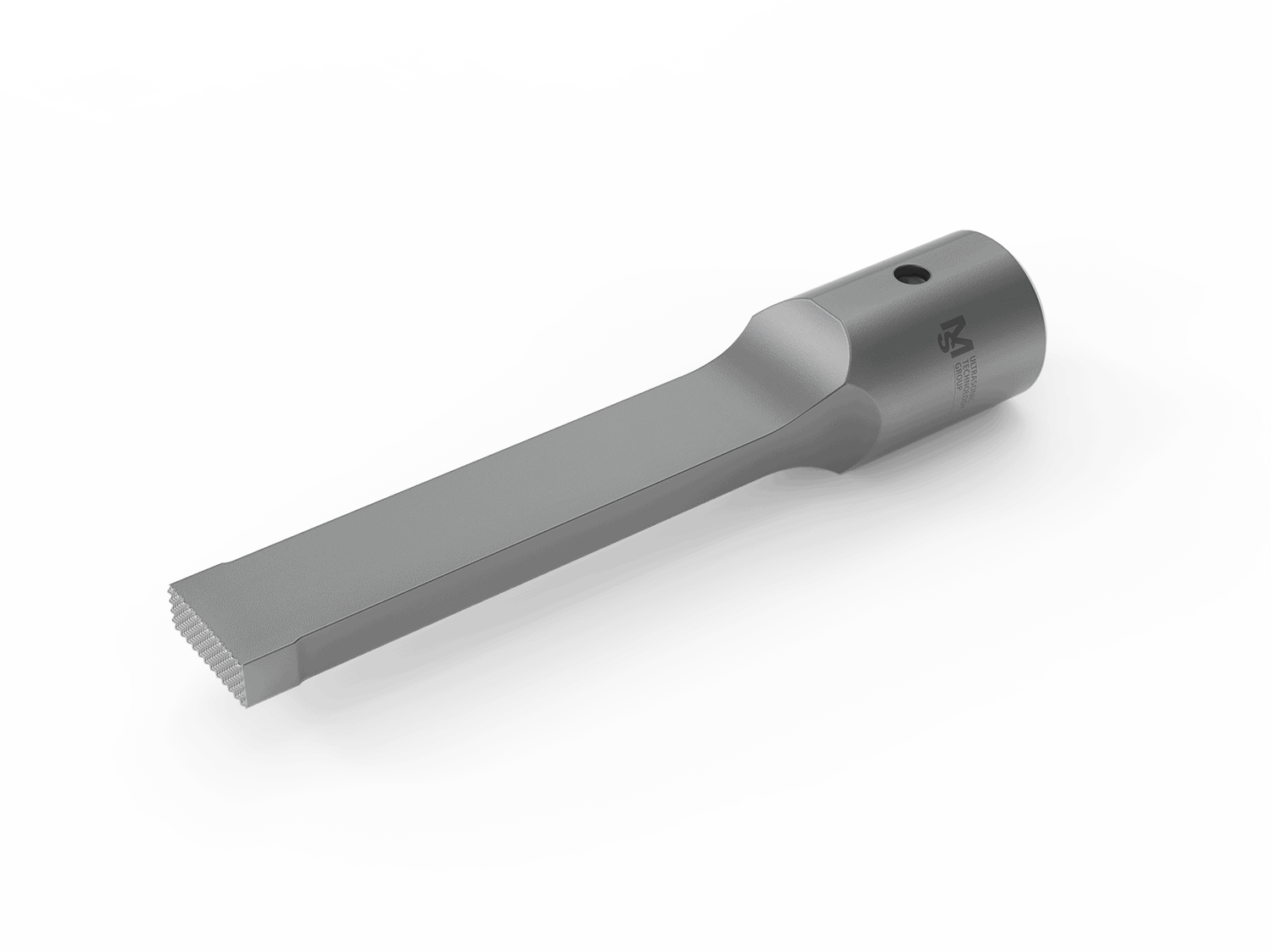

- The torsional sonotrode can always be used in combination with the interchangeable contour screw-in elements (contourtips) and is thus quite variable

- Due to the rotational vibration, there is almost no stress in the join components (about one tenth less, in comparison with longitudinal ultrasonic welding)

- “Torsioning” allows very large forces and power to be introduced into the welding surface – as a result, thicker workpieces can also be joined with great stability

- Higher compaction of the weld point and thus an even more stable connection than with classic longitudinal ultrasonic welding

- Especially suitable for applications in the medical or automotive industry

- Process which is gentle on parts (functional safety remains intact)

- Notch effect and material thinning in film applications is considerably reduced

- Switch between longitudinally and torsionally vibrating sonotrodes is possible at any time through the use of standard components

- Cost-efficient solution for torsional ultrasonic welding through the use of standard components (converter, generator)

- Contour tips available in steel, thus more durable

EXAMPLES

- DAE (pressure equalization element) membranes

- Membrane applications (e.g. degassing valves)

- Medical droplet chambers (e.g. infusion filters)

- Filters

- Thin injection molded parts (nozzles, valves, connecting pieces)

- Difficult injection molding structures (e.g. loud speaker grilles in door side trim panels)

- Sensitive films (for coffee capsules)

- Painted plastic parts

- Oil dampers (in the furniture industry)

VARIANTS

Feed unit from MS sonxMAC custom machine with torsional sonotrode

MS sonxTOP series machine with torsional sonotrode

TECHNICAL DATA

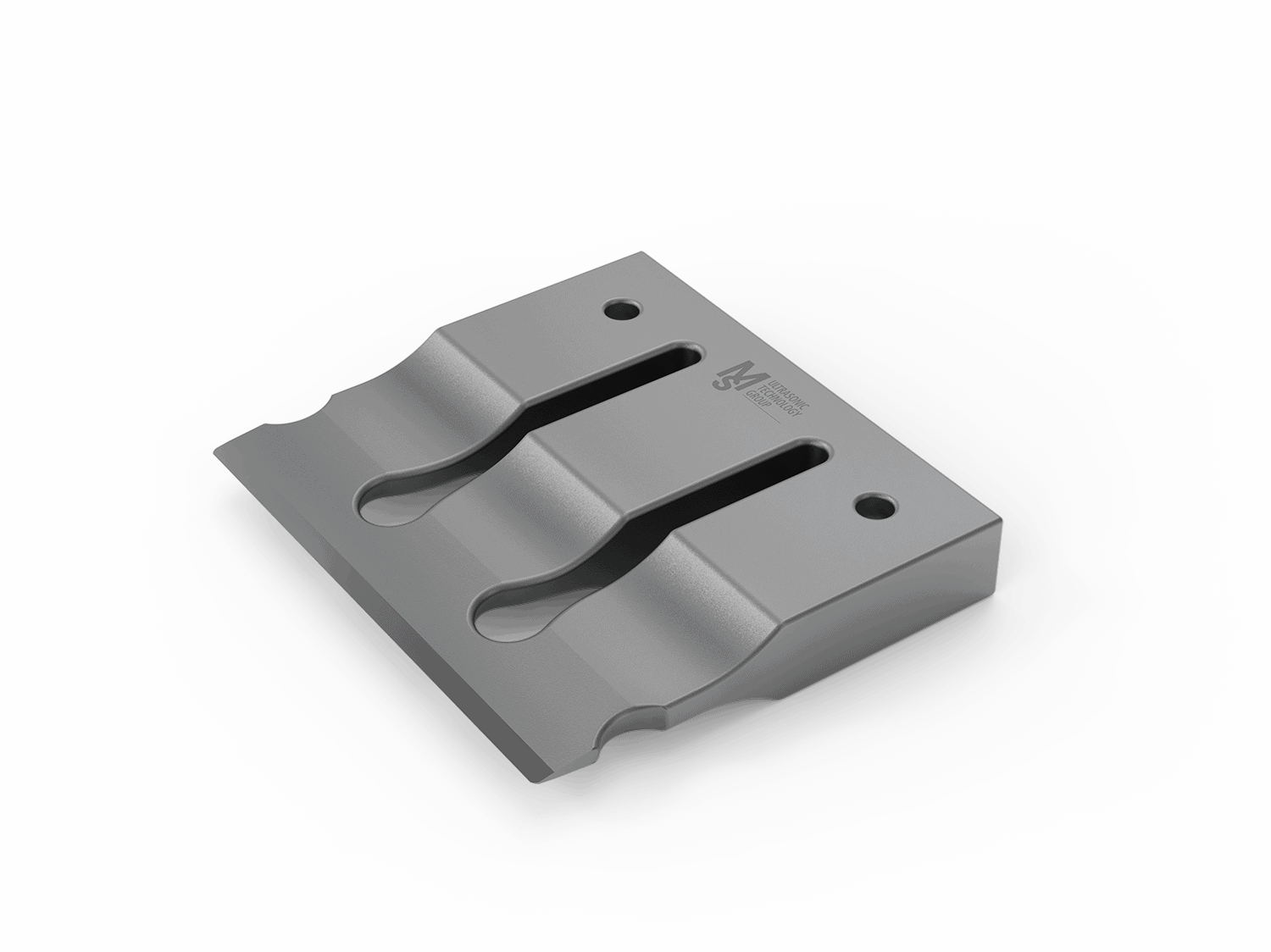

| Sonotrode material | Titanium |

| Contour tip material | Titanium, steel (hardened) |

| Operating frequencies | 20 kHz, 35 kHz |

PRODUCT INQUIRY

Always there for you

Do you have any questions about the product or a special application? We are happy to help you. You are welcome to send us an e-mail at vertrieb@ms-ultraschall.de.

But some things have to be discussed personally. Use our callback form. We will contact you. Fast and competent.