MS sonxSYS COMBINE

In addition to the aforementioned activities of the company, MS has set another priority in the area of continuous welding of nonwovens and other materials.

Over 30 years of experience in the development and manufacturing of high-quality and innovative ultrasonic components, combined with know-how in drive and control technology allows the company to step right into the new business segment seamlessly. Thereby providing the customers with ready to integrate systems with the highest precision from one provider. With the new MS Competence Centre in Ettlingen (Germany) MS is fulfilling the wishes of many customers by expanding the application portfolio with the areas of continuous joining, stamping, and perforating of nonwovens and packaging sealing.

MS is expanding with an innovative and specialised location while retaining a high in-house production depth and support of all departments with the main location in Spaichingen (Germany).

Quality and reliability are the key to success. Considering that the equipment in the nonwovens processing industry produces 24 hours a day, almost 360 days a year results in the requirements for high reliability of the components.

The increasing demands from the industry for faster and faster production lines then inevitably lead to technical requirements for maximum mechanical precision, high ultrasonic power and fast process control.

TECHNICAL BENEFITS

- Newly developed ultrasonic generator MS sonxGEN PREMIUM is capable of delivering a continuous output of 3.5 kW, maximum peak power available 6 kW

- Oscillating systems with rectangular and trapezoidal sonotrodes are available in standardised widths from 85 mm to 270 mm

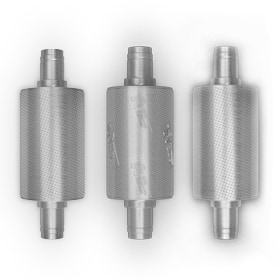

- Various rotating sonotrodes are available in 30 kHz and 20 kHz, in different widths

- The special bearing and guide concept of the servo-electrically driven feed unit offers maximum precision for fast and minimal process adjustments without guide friction at the operating point

- The simple and intuitive operable interface of the control system offers a wide variety of options for welding process design

- Engraved rolls, custom made in house, with complex welding patterns, surface-hardened to increase wear resistance with bale widths of up to 1,000 mm

MS sonxSYS COMBINE STC

- Standing sonotrode with embossing roller with touch panel

- For large area laminations also for high production rates

MS sonxSYS COMBINE ROC

- Rotating sonotrode with embossing roller with touch panel

- Welding of long seams

Embossing roller, bearing mounting, mounting plate

- Welded console

- For absorbing high welding forces

MS sonxCOM ROLL

- In-house manufactured engraving roller

ULTRASONIC TECHNOLOGY

For continual ultrasonic welding the mechanical vibrations are transferred to nonwovens by applying pressure. Through the friction of molecular and boundary surface of the individual workpieces, warmth is created that allows the absorbing coefficient of the material to increase. Point by point the nonwoven starts to melt. The reproducibility and welding quality is paramount for processing continuous sheet materials.

The continual welding and continuous operation makes continuous welding joints without interruption possible.

The ultrasonic technique is a very good alternative to other joining and cutting processes with high efficiency and broad forward-looking possibilities. In contrast to other processes there is no damage to the product itself – no matter which process – cutting, sealing, welding, cut and seal, punching, or riveting.

ADVANTAGES

- Very short processing times

- Minimal to no disturbance of the workpiece with cold welding tools

- Low energy needs for welding and thereby a high efficiency factor

- No solvent or additives necessary (unmixed recycling)

- Enables reproducible welding results over a variety of welding parameters

- Various thermoplastic materials can be welded together

- The welding tools do not heat up, thereby dispensing with warm-up and cool-down times and the tools can be quickly changed out

- No risk of injury by hot machine parts

- Very good integrability into existing systems

- Opportunity to use intelligent networking and automatic control – Industry 4.0

- Energy saving compared to conventional joining technologies

- No additional supplies (e.g. glue) necessary

- High material web speeds possible

- Softness of the nonwoven is maintained due to the precise application of energy to the jointing points

- High stability with multi-material joints

- Constant, speed independent product quality

- Elasticity behaviour of elastic joints are not affected

- Maximised filtration performance via minimised joining surface

APPLICATION AREAS

FURTHER INFORMATION IN OUR BROCHURE AND FLYER

PRODUCT INQUIRY

Always there for you

Do you have any questions about the product or a special application? We are happy to help you. You are welcome to send us an e-mail at vertrieb@ms-ultraschall.de.

But some things have to be discussed personally. Use our callback form. We will contact you. Fast and competent.