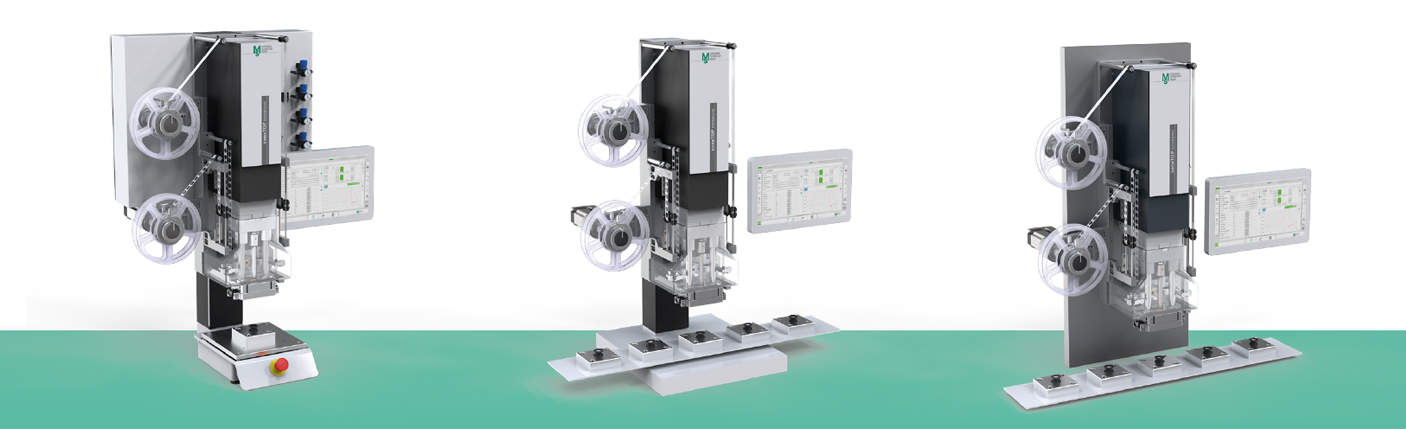

Whether as a manual workstation or seamless integration into an automation system – our modular solution MS sonxTOP MEMBRANE combines membrane punching and sealing in one process step and offers a cycle time of less than 2 seconds.

The series machine is characterised by outstanding features:

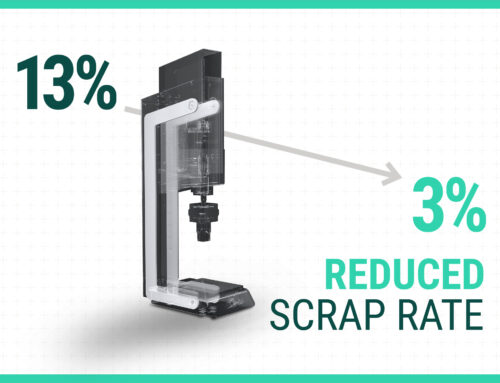

👉🏻 Material savings due to individually adjustable cycle widths

👉🏻 Optionally with patented torsional technology for innovative membranes without PFAS (perfluorinated and polyfluorinated chemicals)

👉🏻 Punching diameters from 8 to 64 mm

👉🏻 Operating frequency of 35 and 20 kHz

The MS sonxTOP MEMBRANE offers numerous unique selling points, including integrated leak testing and belt monitoring, splice point control and quick roll change. Our innovative quick tool change system also allows tools to be changed in under 5 minutes without the need to adjust the gap between the sonotrode and punching die.

More information on our product page.