USP Electric Drive Welders: The MS Ultrasonic Advantage

At MS Ultrasonic Technology Group, we specialize in intuitive, advanced ultrasonic plastic welding technologies designed to work with the industry’s most effective, high-quality materials. Our welding equipment is compatible with a range of thermoplastics, textiles, and nonwovens so that we can provide comprehensive options and turnkey solutions to our customers.

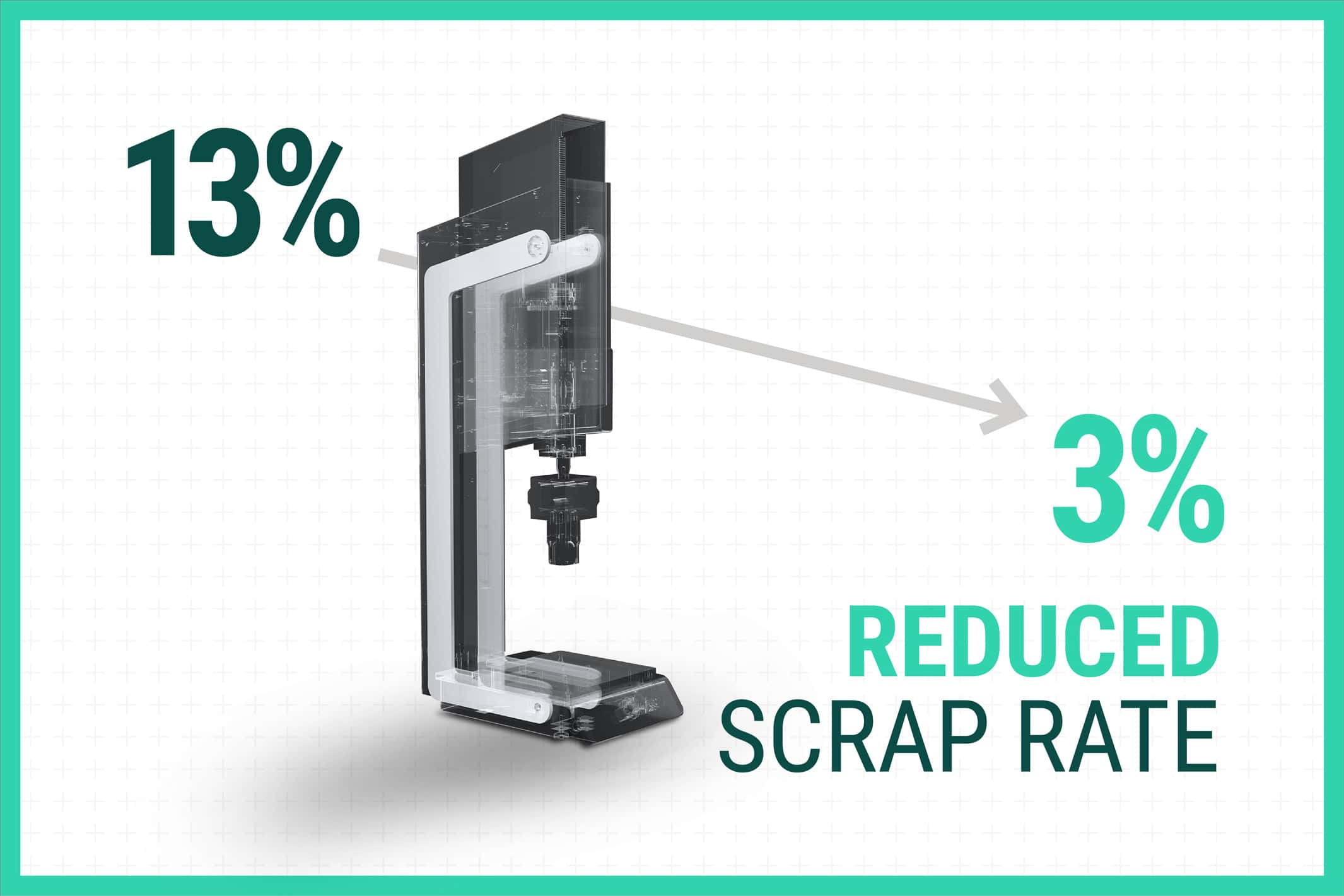

One of our offerings in the ultrasonic plastic welding market is the USP Electric Drive Welder. Emphasizing efficiency and speed without sacrificing precision and weld quality, the servo-electric drive offers maximum control over the welding process for thermoplastics, with accuracy within 10 microns. Learn more about the effectiveness of the ultrasonic plastic welding process as well as the benefits and applications of MS Ultrasonic’s welding systems.

Understanding Ultrasonic Plastic Welding: The MS Ultrasonic Method

Ultrasonic plastic welding achieves solid-state welds in a workpiece by utilizing high-frequency ultrasonic vibrations and pressure. These mechanical vibrations produce the heat necessary to create a welded joint within milliseconds — a stark contrast to the slower weld times of alternatives like traditional or vibration welding. The ultrasonic plastic welding process melts components’ thermoplastic material, fusing parts together and creating a strong yet aesthetically pleasing bond between them. As a result, this welding method does not require any glues or other consumable materials.

It’s our commitment to customization at MS Ultrasonic that defines our leadership in the field of ultrasonic plastic welding technology. We aim to provide turnkey, scalable solutions through advanced, customizable ultrasonic plastic welding equipment. Our team is skilled at in-house machine building, enabling us to efficiently produce versatile tooling and machinery per your specifications to meet virtually any application requirements. Our custom manufacturing capabilities set us apart from some of our competitors in the market who are limited to solely customizing standard table-top welders.

Why Choose MS Ultrasonic’s Electric Drive Welding Equipment?

For the full duration of the welding cycle, Servo Electric Drive Welders from MS Ultrasonic epitomize control, precision, and repeatability, outperforming traditional pneumatic alternatives. We’ve designed our equipment to simplify the welding process so that all you have to do is load the files, set the tool stack, and start the operation.

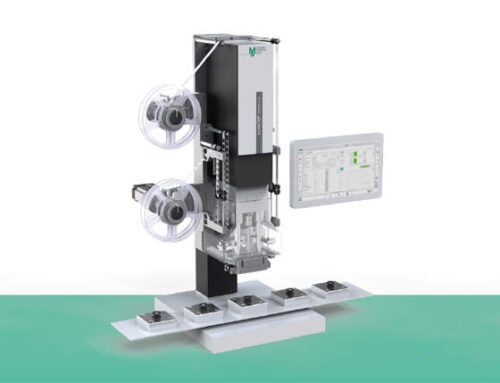

Our welding equipment combines components such as scanners, input/output (I/O), and servo-driven XY tables, as well as external welder testing, into a single system. We’ve also incorporated safety features, including an air management alarm should pressures exceed safe levels, as well as capabilities like toolless changeovers to enhance efficiency. Our human-machine interface (HMI), which our team designed from the ground up, facilitates control of air-driven actuators and difficult-to-place sensors rather than relying on third-party programmable logic controllers (PLCs).

Our sonxTOP series specifically allows for barcode scanning, RFID, and digital I/O compatibility with differing heights. The machines’ advanced sequencing software package, digital controls, and intuitive HMI are easy to use, necessitating minimal training for operators.

Importantly, these machines seamlessly integrate into production lines to simplify installation and minimize downtime. With MS Ultrasonic’s customization capabilities, we can tailor your equipment to fit your existing line and fulfill the needs of diverse applications.

Applications for Ultrasonic Plastic Welding Equipment

Servo Electric Drive Welders from MS Ultrasonic are at the forefront of ultrasonic plastic welding innovation, delivering unparalleled versatility to suit a wide range of industries, thermoplastic materials, and customer requirements. Common markets that benefit from ultrasonic plastic welding include the following:

- MS Ultrasonic technology solutions like the USP Electric Drive Welder excel in producing strong, durable packaging without the need for glues or related adhesives. This welding technique results in durable packaging solutions that decrease waste.

- For automotive components, especially small or complex parts, the precision and repeatability of MS Ultrasonic’s sonxTOP machine series and USP Electric Drive Welders ensure uniform, high-quality welds essential for vehicle safety and performance.

- The welding technique’s ability to create clean, strong, and hermetically sealed bonds without introducing contaminants or chemicals makes it ideal for medical device manufacturing. These welds offer biocompatibility, can withstand degradation from routine cleanings, and are suitable for cleanroom equipment.

- With our background in joint design, MS Ultrasonic creates equipment that generates reliable welds capable of withstanding rugged applications and harsh environments in the industrial sector.

Elevate Your Production With MS Ultrasonic’s Advanced Ultrasonic Plastic Welding Equipment

MS Ultrasonic’s USP Electric Drive Welders deliver heightened efficiency, speed, accuracy, and quality for manufacturers looking to upgrade from traditional welding technology. To explore how MS Ultrasonic can transform your production processes with our advanced ultrasonic plastic welding equipment for plastic, contact us today.