How to achieve stable and repeatable welding results with soft Polypropylen (PP) and complex parts?

Ultrasonic welding technology has continued to develop, enabling results that were unattainable just a few years ago. Fast, clean and extremely efficient, due to an accuracy to the millisecond. The new possibilities of welding were not only achieved by modern multi-core microprocessors, which ensure up to 1,000 control cycles per second, but also thanks to the increasingly widespread use of servo motors. The resulting great application flexibility ensures that a welding process can be divided into 13 fully adjustable phases.

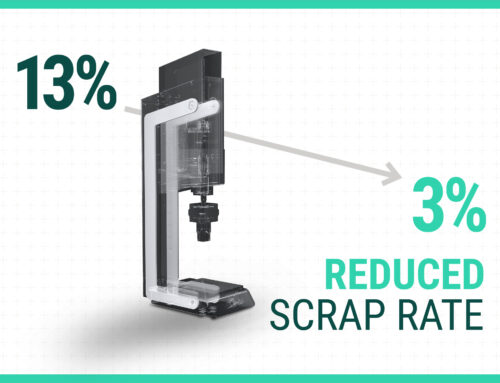

The electronic servo control ensures repeatability of results which until now is unattainable with classic proportional valve controls due to the random nature of the compression and circulation of the compressed air.

Applications, especially in the medical and automotive sectors, but also in the consumer sector, benefit particularly from these innovations. Ultrasonic welding has become the primary assembly process and, due to its advantages in terms of precision and cost-effectiveness, has eclipsed comparable technologies such as joining with vibration, hot plates and lasers.

Complex techno-polymers with high melting temperatures such as PA (polyamide), PPS (polyphenylene sulfide) and even PEEK (Polyether ether ketone) are processed safely and with maximum precision. For each single weld, more than 200 parameters can be verified, archived, and analyzed. Among all the complex polymers that can be ultrasonically bonded, PP (polypropylene) is perhaps one of the most interesting materials, as there are more than 5,000 types on the market, and often the behavior is completely different even for very similar polymers. The reality is that PP, due to its mechanical and chemical resistance characteristics and, naturally, thanks to its reduced cost compared to other polymers, is one of the main choices of the technical industry.

Welding process requirements

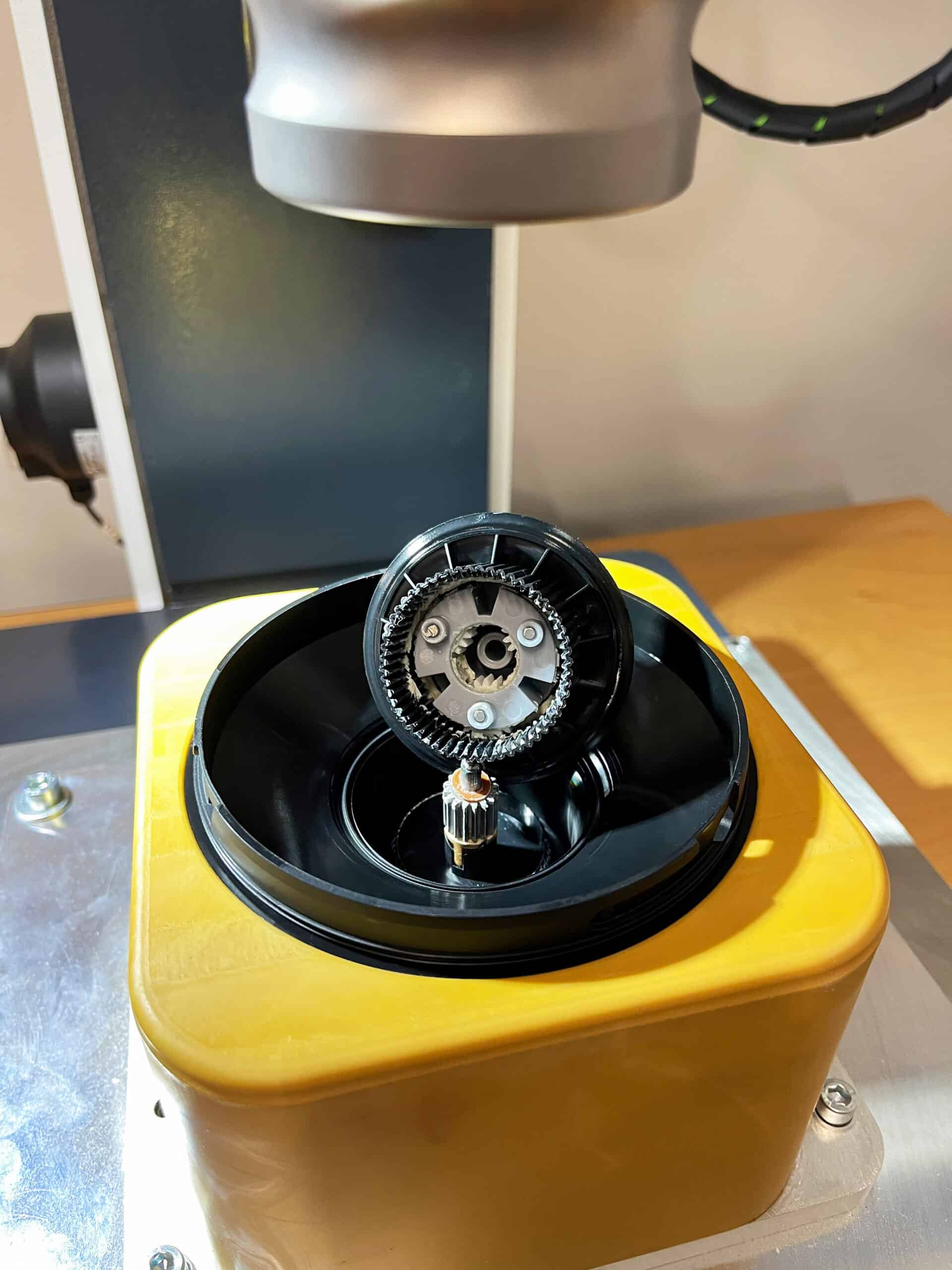

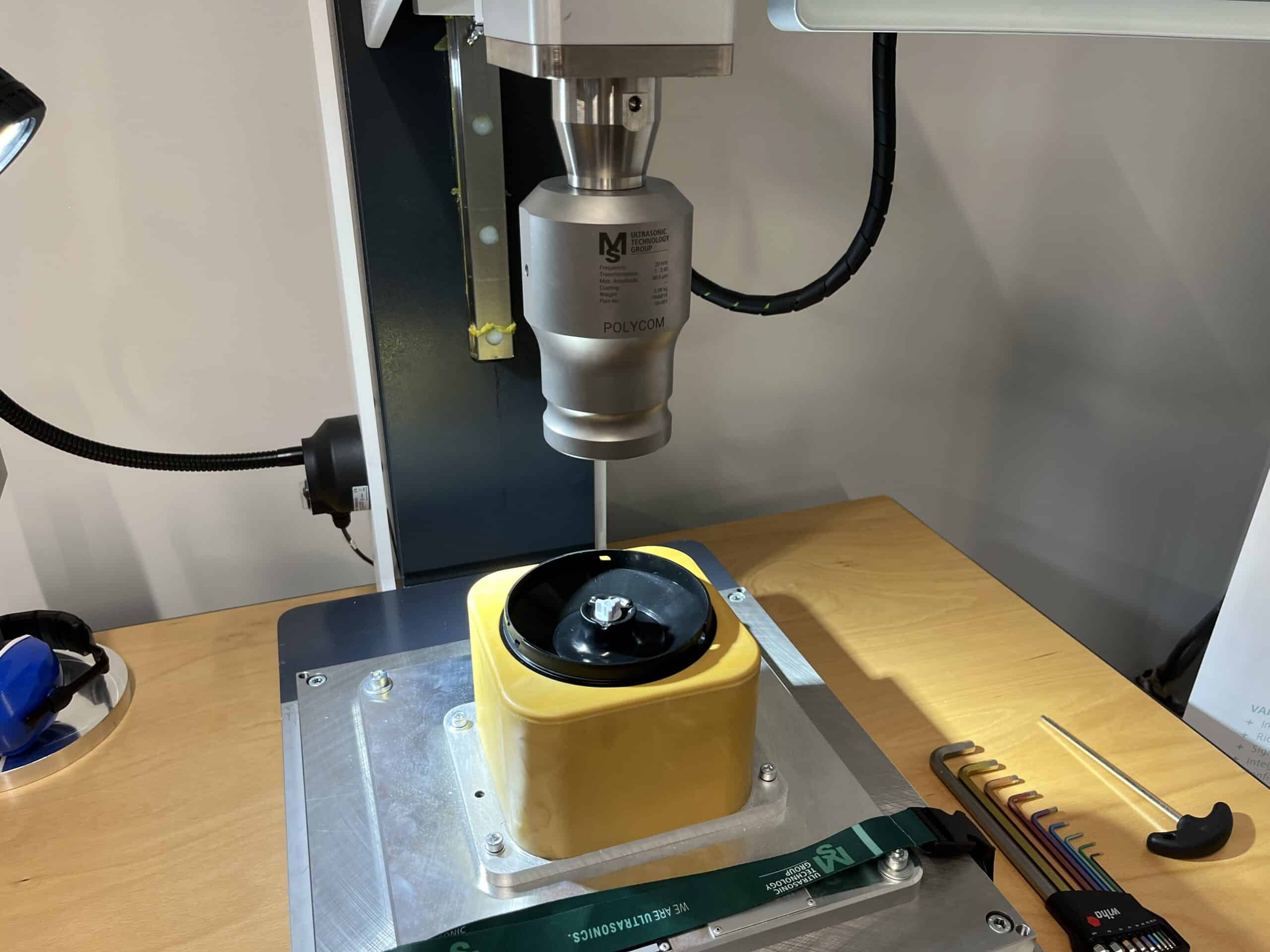

In cooperation with the Slovenian company Polycom and Bosch Home Appliances, an ultrasonic welding solution was investigated to ensure the perfect connection of an aesthetic element made of PP, which is part of a household appliance. For each detail, hermetic sealing and mechanical functionality had to be ensured, because there were precision gears inside. Classic methodologies would not have allowed repeatability of such a complex weldings, so we had to study a process that considered both the high damping of the PP and the precision required by the internal gears.

Technical realization

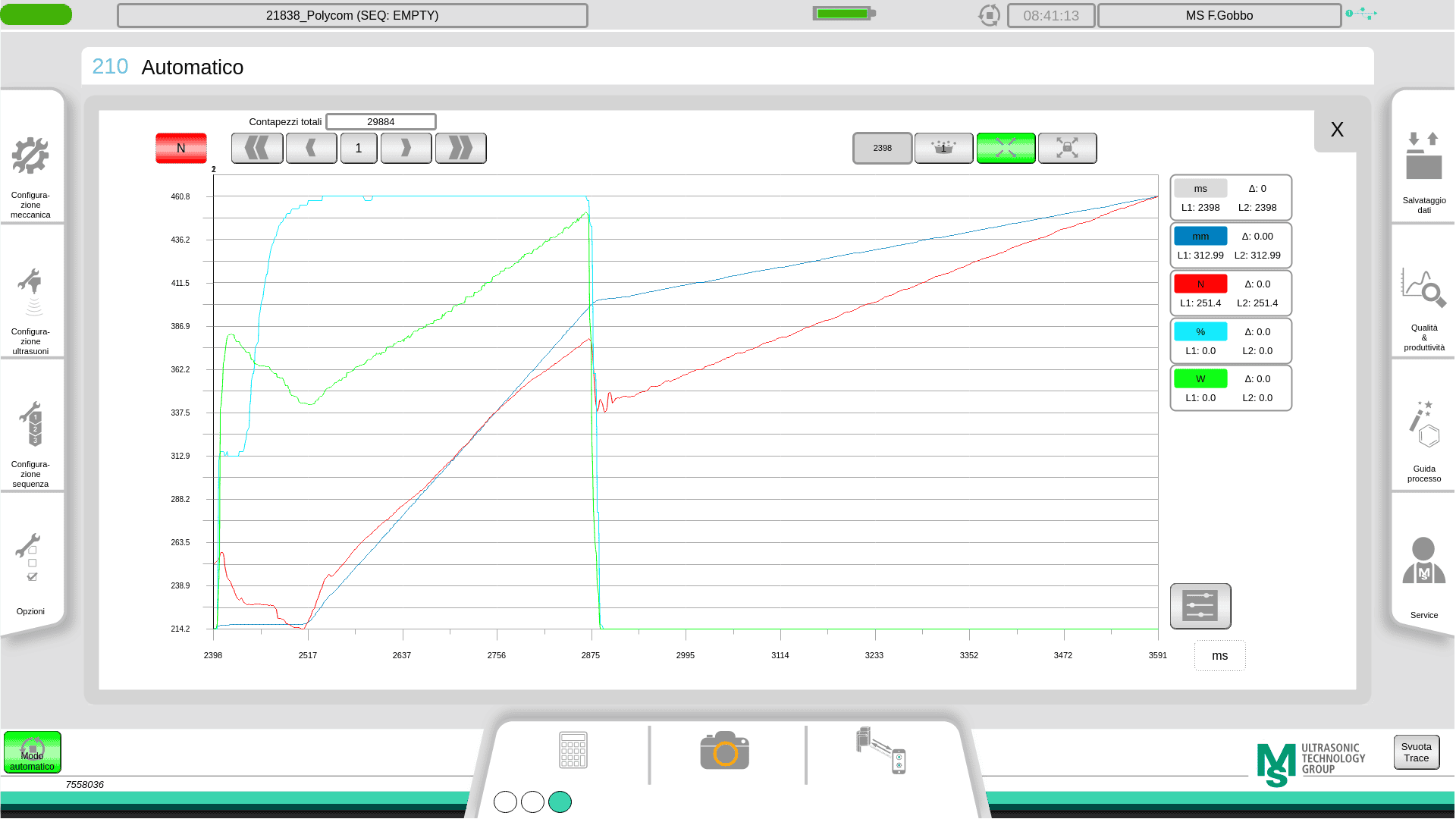

The first trigger phase had to be extremely precise to ensure that the welding always started at the same contact point. The precise load cell used, and the servo motor were of fundamental help. Welding had to begin only when 250 N of compression was reached.

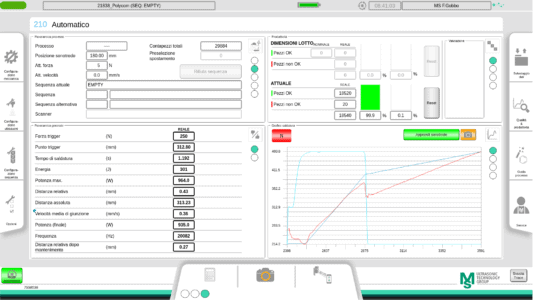

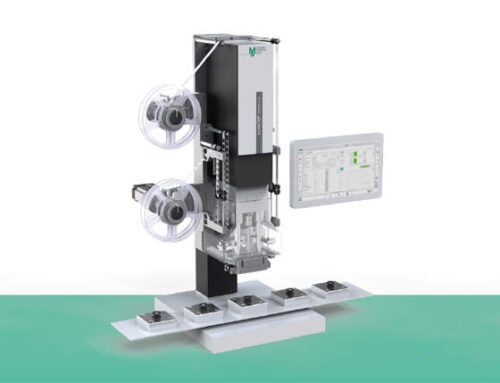

Parameterization of the two phases in the intuitive user interface of the

MS sonxTOP series machine.

The fusion phase has been split in two. First a heating phase with the sonotrode stopped, then an advance at a controlled melting speed of 1.2 mm/s. To compensate for part tolerances, force alone was not enough. The fusion speed ensured that the force was adapted to the actual mating conditions from time to time. To ensure maximum welding precision of ± 0.03 mm, the holding phase was also divided into two phases. An initial hold, controlled in speed and position, and a final compression to strengthen and finally fix the structure of the PP.

The project was successfully realized thanks to the technological know-how and the advantages of our MS sonxTOP ultrasonic welding machines.