Conditorei Coppenrath & Wiese KG is the European market leader in frozen cakes, tarts and baked goods and employs more than 2,600 people in Germany (2018). The company has been part of the Oetker Group since 2015.

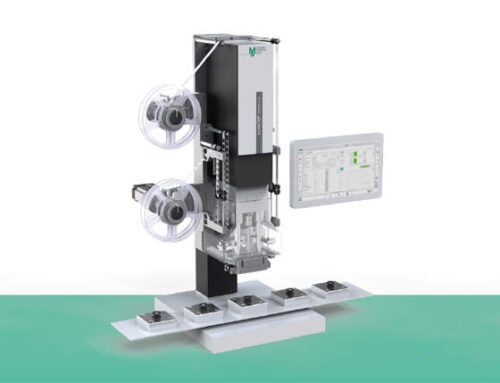

After baking, the cakes are portioned by ultrasonic cutting technology. The ultrasonic knives (sonotrodes) are activated with a frequency of 20,000 Hz – with this dynamic, the cutting resistance is reduced, the cut is cleaner and the knife is self-cleaning. “Critical products such as the classic bee sting with the almond layer on top, which is quite hard after all, underlaid with dough and a soft cream layer on top of that, would not be feasible without ultrasound, neither in the suitable cutting quality nor in the cutting speed,” says Manfred Freude, head of the maintenance department at Coppenrath & Wiese.

The company likes to be called the most modern bakery in Europe and so it is not far-fetched that they have brought a competent partner into the house with the Swabian innovation leader MS Ultraschall Technologie GmbH. “We have known the problems of cutting very well for many years and can thus offer extremely stable equipment that, in addition to durability and the perfect cutting result, can even boast the advantage of lower noise emissions,” adds Konrad Beretitsch, Sales Manager Systems&Components. “In addition, completely different laws apply in some cases when cutting food; cheese behaves differently from cake or sausage or a chocolate bar, and this knowledge is not available in textbooks; you have to work it out and gain experience that way,” adds Thomas Fischer, Technical Manager of MS’s Competence Center Ettlingen.

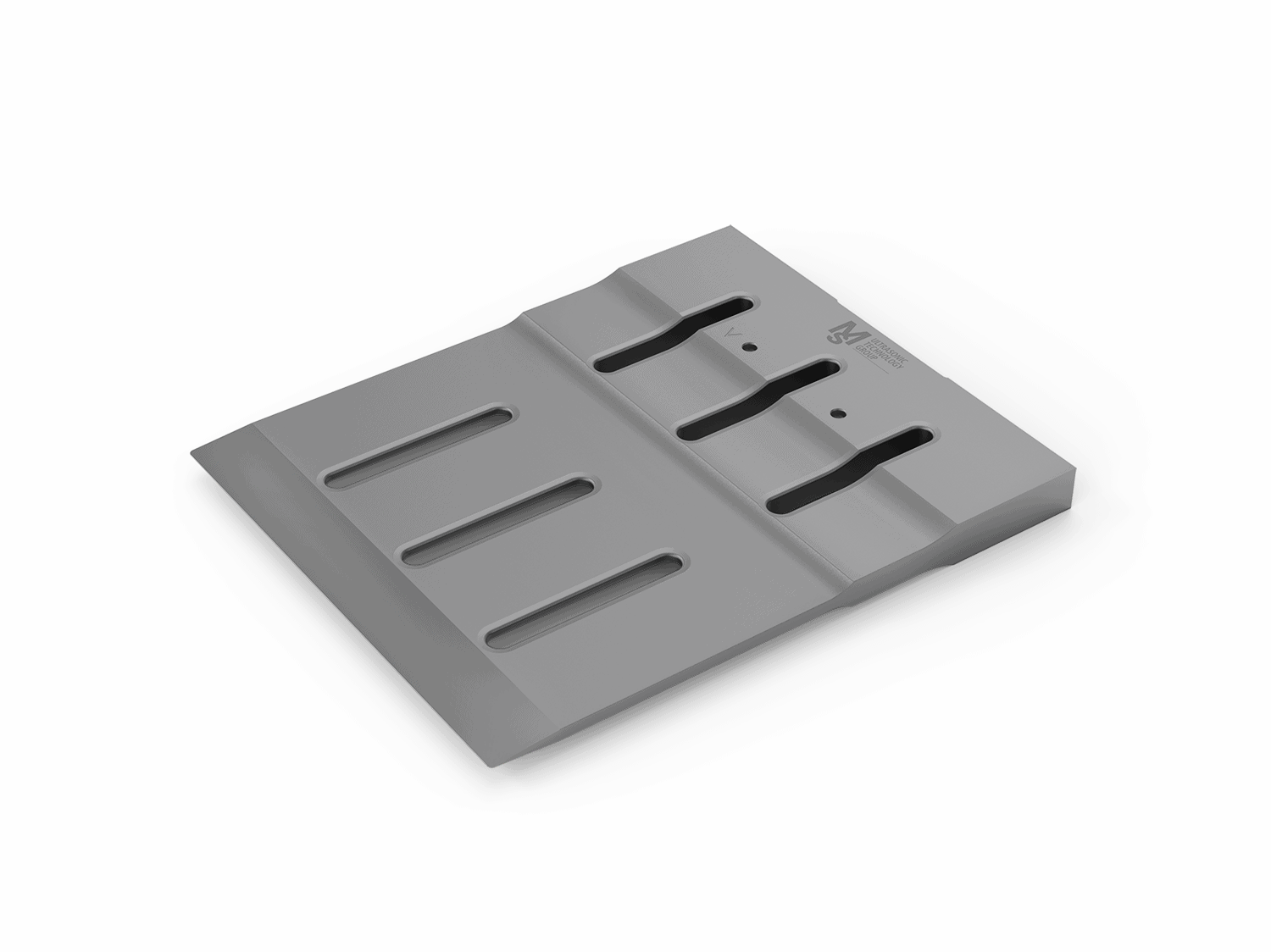

“We’ve been promised a lot, but we’ve often been kept to very little,” says Manfred Freude, drawing on his experience from past years, and so we first installed MS on a test basis. The equipment from MS not only met our expectations, but exceeded them by far, and so after the tests we converted most of our cutting lines to MS technology and are highly satisfied. In addition, they not only supplied us with the components, but also used their in-house advantage of being a machine builder: we were able to obtain ready-to-install conversion kits with guides, drives, etc., which reduced the conversion time to a minimum,” continues Manfred Freude.

“The guys from the maintenance department at Coppenrath & Wiese are really on their toes and do a great job, so that the rebuild went hand in hand and we only needed help with the fine-tuning,” praises Alexander Braun, who led the commissioning on site from MS.

This is an example of how professional companies can work together to achieve joint success.

For more information about our Cutting systems please click here

or contact the sales office at any time by phone or email:

+49 7424 701-800